Piyali Group Corporation is the proud designer and manufacturer of high-quality 200 TPD rotary kiln pinion assembly products that acknowledges as some of the best in the sector. Our products perform a variety of functions in many factories and industries. Automotive, Industrial, robotics applications and consumer goods are just a few of the industries that frequently use pinion gear assemblies. Proper maintenance and inspection is necessary for the kiln pinion to operate safely and efficiently.

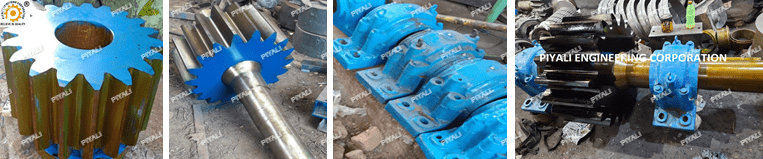

The 200 TPD rotary kiln pinion assembly consists of various parts such as kiln pinion, kiln pinion with shaft, kiln pinion with plummer block, kiln with bearing and lubrication system. The assembly includes a mounting block with a bearing inside of it.

KILN PINION ASSEMBLY PARTS:

STEP 1: PINION GEAR

PIYALI GROUP manufactures, supplies, and exports high-quality pinion gear with small or large teeth to mesh with a spur gear. Pinion gears are essential parts in several industrial applications, and their design and production requires knowledge and reliability to guarantee stable and effective performance. An essential component of the 200 TPD kiln pinion assembly in a DRI sponge iron plant is the kiln pinion or pinion gear. A pinion gear is a small(pinion) gear that meshes with a larger(girth) gear and work in pairs to transfer and adjust rotary motion and power.

STEP 2: PINION SHAFT

A shaft is a long cylindrical rod that transmits power or motion from one portion of a machine to another. The pinion shaft’s job is to connect the pinion gears to the steering shaft so that when the steering wheel turns, the gear spins and moves the spur gear. The shaft is the main part of the 200 TPD rotary kiln pinion assembly.

STEP 3: PLUMMER BLOCK

A Plummer block, also known as a pillow block bearing, is a form of bearing housing used to support a rotating shaft. A bearing that supports the rotating shaft is located inside the housing. For the purpose of lubricating or maintaining the bearing, the plummer block features a removable end cap or cover. They provide an easy and effective method for maintaining spinning shafts while avoiding noise and vibration. The shape and dimensions of the plummer block determines by the size, speed, and weight of the shaft, as well as by the application’s environmental circumstances.

KILN PINON ASSEMBLY FOR DRI SPONGE IRON PLANTS:

- Kiln Pinion

- Kiln Pinion with Shaft

- Kiln Pinion with Plummer Block (Bearing house assembly)

- Kiln with Bearing

- Kiln End Plate & End Cover

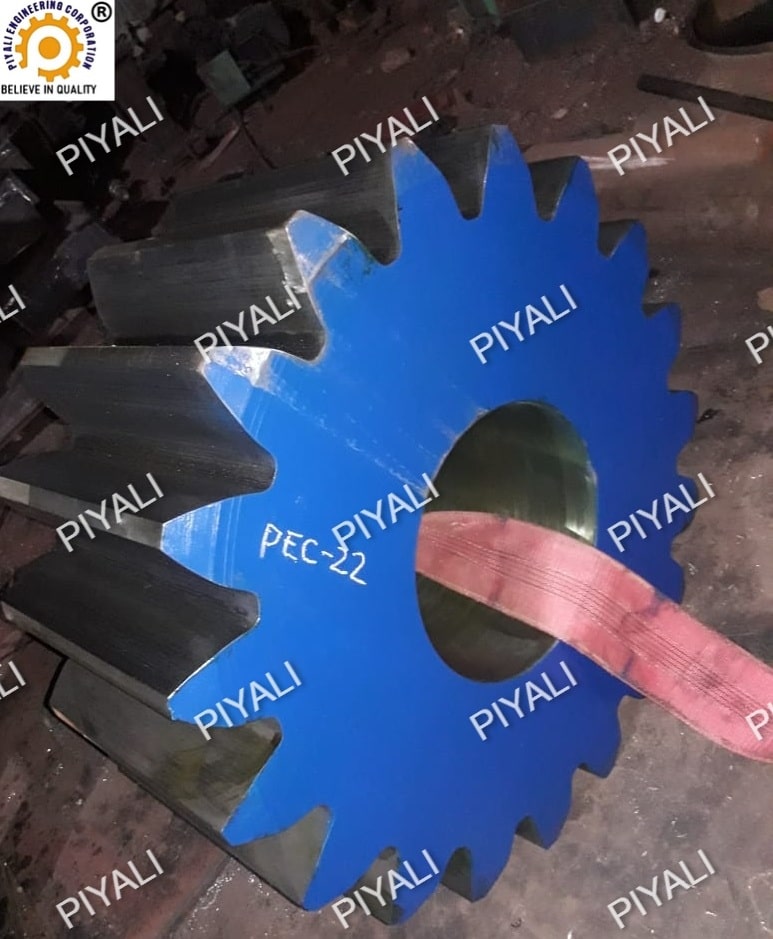

1. PINION GEAR:

A pinion gear is a part of 200 TPD kiln pinion assembly, also known as kiln gear, used in several manufacturing processes, including the production of cement,mineral processing, creation of chemicals, and the production of an iron ore (Iron ore pellets and other materials. This is a small gear with fewer teeth than the larger gear it meshes with, called the “ring gear”. The purpose of the kiln pinion is to transfer power from the kiln drive system to the rotating kiln shell, which supports two or more rollers. A rotating gear meshes with a pinion, usually made of forged steel, with a diameter around the teeth.

The teeth on the kiln pinion may break down or suffer damage over time, which may cause the kiln to vibrate excessively, make a loud noise, or fail to rotate properly. The kiln pinion needs to be fix or repair properly in such situations. Regular maintenance and inspection of the drive system of the kiln is necessary to ensure optimum performance and durability.

200 TPD Kiln Pinion Gear Technical Specifications

- MODULES – 40 Module

- CAPACITY – 200 TPD Rotary Kiln Pinions for Sponge Iron Steel Plant

- CERTIFICATION – ISO9001

- No of Teeth – 19

- MATERIAL GRADE – IS-2708 GRADE II, IS-2644 GRADE II, EN-19, EN-24 FORGED

- DESIGN – AS PER CUSTOMER PROVIDED (POPURI / IPS / ITC / MEC / LURGI etc.)

FEATURES OF PINION GEAR:

- Pinion gears are generally cylindrical in form and their teeth cut into the circumference of the gear.

- Simpler in design.

- The distance between adjacent teeth refers to as a pinion gear’s pitch.

- Proper lubrication is a necessity for pinion gears to prevent wear and damage from friction.

- Small and light in weight.

- A pinion gear reduces the speed of a rotating shaft. By using a pinion gear, the output shaft can rotate at a lower speed than the input shaft.

- Excellent customer service.

2. PINION SHAFT:

An essential part of the rotary kiln device is the pinion shaft. A cylindrical shaft that connects the kiln drive system to the rotary kiln. The rotary kiln rotates due to the torque generated by the kiln drive system through the pinion shaft, which allows it to process the materials in the kiln. This improves the shaft’s strength and, as a result, its capacity to withstand the significant torque. By coupling the motor and the rotary kiln, it transfers the force that the motor produces to the rotary kiln, which rotates the material inside. A pinion gear, a shaft, and bearings usually make up the pinion shaft.

PINION SHAFT KEY:

A shaft key is a tiny, rectangular piece of metal that fits into a keyholes or slot on the shaft. The key transmits the force from the shaft to the driven part, such as a gear or a pinion, as the pinion shaft rotates. In order to lock the key in position, the retaining nut or bolt must be tightened into the keyway on the shaft and gear.The key is essential in transferring torque from the pinion gear to the shaft, which enables the gear to spin and power additional parts like a differential or transmission. Without a correctly fitted key, the gear may slip or become out of alignment, which could impair performance or harm the engine. In rotary kilns, pinion shaft keys secure the pinion shaft to the kiln shell and enable movement of the kiln.

PINION SHAFT GEAR COUPLINGS:

Pinion shaft gear couplings are mechanical parts that join the pinion shaft of a motor or engine to other moving parts, like a gearbox or transmission. The coupling is made up of two halves, each with internal teeth that mesh with the exterior teeth of the pinion shaft and the other rotating component. Pinion shaft gear couplings are made to transfer torque between the parts while adjusting for any rotation or misalignment. The gear teeth offer a solid connection that enables the transfer of power without slippage or loss of effectiveness.

WORKING:

A pinion shaft gear coupling is usually installed by attaching one half to the pinion shaft and the other to the driven shaft. The teeth then mesh to form a connection as the two halves are pulled together. When the coupling is put in place, it enables the rotation of the two axles while correcting for any possible misalignment. This kind of coupling is frequently used in equipment like rolling mills, heavy machinery, and mining machinery where misalignment is frequent.

200 TPD Kiln Pinion Shaft Technical Specifications

- MODULES – 40 Module

- CAPACITY – 200 TPD Rotary Kiln Pinion Shafts for Sponge Iron Steel Plant

- CERTIFICATION – ISO9001

- No of Teeth – 19

- MATERIAL GRADE – IS-2708 GRADE II, IS-2644 GRADE II, EN-19, EN-24 FORGED

- DESIGN – AS PER CUSTOMER PROVIDED (POPURI / IPS / ITC / MEC / LURGI etc.)

FEATURES OF PINION SHAFT:

- Pinion gear shafts transmits torque more efficiently than other types of shafts, which reduces frictional losses.

- Pinion shafts transmit power over long distances without significant power loss.

- Pinion shafts design to endure higher loads and stresses, which makes them more durable and reliable than other types of shafts.

- Pinning shafts are extremely versatile and can be used in a variety of applications, from automotive to industrial machinery.

- Pinion shafts are easy to maintain and repair

3. PLUMMER BLOCK:

A Plummer block, also known as a pillow block bearing, is a form of bearing housing used to support a rotating shaft. The plummer block has an important function in the smooth and effective operation of the rotary kiln system. It is important to perform routine inspections to look for wear or damage indicators like cracks, corrosion, or excessive wear on the bearing surfaces. The base and the cap are the two main components of the plummer block that bolt together around the bearing. For the plummer block to operate effectively for a long time, proper greasing is also essential.

200 TPD Kiln Plummer Block Technical Specifications

- MODULES – 40 Module

- CAPACITY – 200 TPD Rotary Kiln Plummer Block for Sponge Iron Steel Plant

- CERTIFICATION – ISO9001

- MATERIAL GRADE – IS-2708 GRADE II, IS-2644 GRADE II, EN-19, EN-24 FORGED

- DESIGN – AS PER CUSTOMER PROVIDED (POPURI / IPS / ITC / MEC / LURGI etc.)

FEATURES OF PLUMMER BLOCK:

- HOUSING: The plummer block assembly includes a housing made of cast iron or steel that is designed to support the bearing and provide a reliable mounting surface.

- PEDESTAL: The pedestal (base), usually made of cast iron or steel. The pedestal is designed to provide a secure and stable base for the bearing.

- END CAP: An end cap in a plummer block is a small metal cover that seals and protects the leading edge of the pinion shaft in a plummer block assembly. The end cover helps maintain the lubricant in the housing of the bearing. This is significant because the lubricant helps reduce friction between the assembly’s rotating components, which can reduce wear and enhance efficiency.

- BEARING: The bearing is a component that enables a shaft to rotate smoothly. The bearing is mounted inside the housing, which protects it from pollution and guarantees proper lubrication.

- MOUNTING SYSTEM: The mounting system secures the bearing to the pedestal. It usually contains a set screws or secure cap that hold the bearing firmly in position and prevent it from rotating within the housing. The mounting surface must be strong and rigid enough to withstand the weight and pressure of the rotating shaft.