A sugar mill is an organization that produces raw sugar from sugar cane or beet sugar. A sugar mill’s primary function is to extract the juice from sugarcane. Then, it processes it to produce different sugar products such as raw sugar, white sugar, and refined sugar. Crushing, grinding, boiling, and crystallization are all stages in the sugar mill that separate the sugar from the plant material and other impurities. Sugar mill equipment are essential for proper operation.

SUGAR MILL TYPES

Here are some common types:

- Traditional Sugar Mills: These mills are the most basic type and use simple methods to extract sugar from sugarcane. The process involves crushing sugarcane using rollers, and then boiling the juice to evaporate the water and crystallize the sugar.

- Diffusion Sugar Mills: In this type, sugarcane is crushed and then soaked in hot water to extract the juice. The juice is then purified and the sugar is crystallized.

- Modern Sugar Mills: These mills use advanced technology and equipment to extract sugar from sugarcane. Automated sugarcane processing machines can process large quantities of sugarcane quickly and efficiently.

- Mini Sugar Mills: These are small-scale sugar mills use simple equipment to process sugarcane.

- Integrated Sugar Mills: These mills not only produce sugar, but also generate electricity and produce ethanol as a by-product.

- Co-generation Sugar Mills: Mills use bagasse to generate electricity from sugarcane.

WORKING PROCESS:

The working process of a sugar mill usually includes the following steps:

- Sugarcane Harvesting: Sugarcane is harvested and carried to the sugar mill for processing.

- Washing and Preparation: To eliminate dirt and other impurities, the sugarcane is washed. It is then cut into tiny pieces and ready for crushing.

- Crushing: The sugarcane is crushed in a succession of mills to extract the juice. The juice is gathered and processed further.

- Purification of Juice: After collecting the juice, it is purified to eliminate impurities such as dirt, fibers, and other solids. This is done by going through a number of filtration and refinement processes.

- Evaporation and boiling: The purified juice is then evaporated and boiled to eliminate excess water and concentrate the sugar content.

- Crystallization: Crystallization produces raw sugar from concentrated liquid.

- Centrifugation: This process separates the raw sugar from the residual liquid.

- Refining: The raw sugar is refined to remove any residual impurities and yield a higher quality, refined sugar.

- Packaging and Delivery: The refined sugar is finally packaged in different sizes and delivered to consumers, manufacturers, and other customers.

SUGAR MILL EQUIPMENT LIST:

Sugar mill equipment refers to the various components and spare parts necessary for the proper operation of the mill.The spare parts may vary depending on the specific equipment and machinery. However, here is a general list of equipment:

- Mill Rollers

- Bearings

- Gears and Pinions

- Shafts

- Couplings

- Sprockets

- Motors

- Pumps

- Valves

- Cane Knives

- Trash Plates

- Top and Bottom Roller Bearings

- Cane Carrier Sprockets

- Juice Heaters

- Evaporators

- Centrifuges

- Turbines

- Condensers

- Cooling Towers

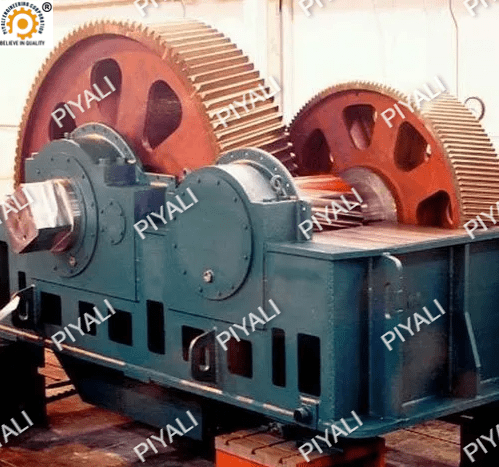

SUGAR MILL GEARS:

PIYALI manufactures sugar mill equipment in accordance with the drawing and the material specified by the client. Wheel gears, crown pinions are available in different sizes and shapes. As construction materials, we frequently use cast iron, cast steel, and gun metal. We never sacrifice on quality, as we provide the best available services to our customers.

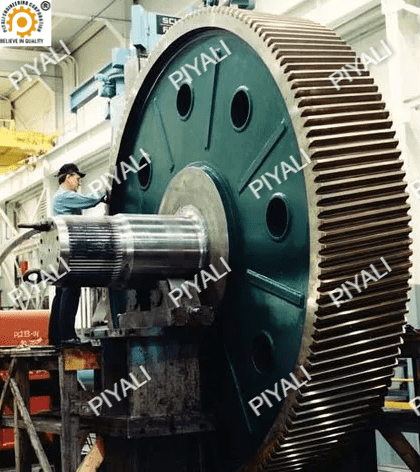

GEAR WHEELS:

A form of gear used in sugar mills to drive the machinery that produces sugar. The gear wheel is the main component of the sugar mill equipment. Its purpose is to transfer force from a rotating shaft to other parts of the sugar mill machinery, such as the rollers that crush sugar cane. Large teeth on the gear typically mesh with corresponding teeth on another gear or a rack, enabling power to transmit between the two components. High-strength stainless steel is used to design sugar mill wheel gears to handle heavy loads.

KEY FEATURES:

- The gear teeth ensure smooth and efficient power transfer, resulting in maximum juice extraction.

- Sugar mill gear wheels are durable and reliable.

- Efficient operation of sugar mill gear wheels can help to improve efficiency.

- High-quality materials, precision manufacturing, and regular maintenance are essential for gear wheels to operate safely and reliably.

GEAR WHEEL AND CROWN PINION: SUGAR MILL EQUIPMENT

The sugar mill wheel gear and crown pinion transmit power from the electric motor to the sugarcane crusher plant. The gear and pinion system improves the machine’s efficiency and enables it to crush sugarcane stalks with ease. Good quality components are essential for successful operation of the sugarcane crusher plant.

The internal gears are typically helical or spur gears, which transmits power from the motor to the cane crushing rollers.

- Spur gear: This type of gear wheel transmits power between parallel shafts.

- Helical gear: This type of gear wheel allows for smoother and quieter operation than spur gears.

- Double-Helical gear: In sugar mills, the use of double helical gears facilitates a greater gear ratio, which causes the machinery to move more slowly and precisely. This is significant when processing sugar because exact machinery control is necessary to produce the desired outcome in terms of both quality and quantity.

ROLLER SHAFT:

The sugar mill roller shaft is one of the sugar industry’s most important components. The mill drive shaft’s main purpose is to crush the sugar cane and separate the juice. Sugar cane is fed into the mill through three drive pulleys and crushed between the feed-top rollers. The garbage plate collects the juice, and the top-discharge roller discharges the bagasse.

SUGAR MILL CROWN PINION: SUGAR MILL EQUIPMENT

A sugar mill crown pinion drives crushing rolls. It is a large gear wheel that connects to the end of the primary drive shaft of the mill that meshes with a smaller gear wheel known as the pinion. The crown pinion rotates as the main drive shaft rotates, enabling the pinion to rotate and transmit power to the mill’s crushing rolls. The dimensions of the crown pinions are up to 2200 mm.

KEY FEATURES:

- The teeth on the crown pinion enable efficient power transmission, resulting in maximum juice extraction.

- Regular inspections and maintenance extends the lifespan of crown pins.

- High-quality materials, precision manufacturing, and regular maintenance are essential for safe and reliable operation.

- Efficient operation of crown pinion can improve sugar production efficiency.

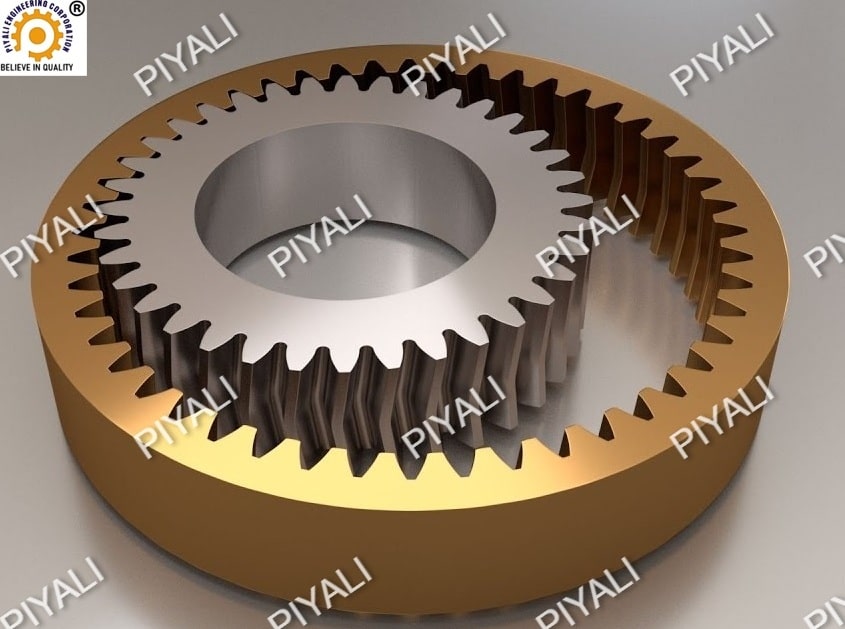

PLANETARY GEARBOX: SUGAR MILL EQUIPMENT

A sugar mill planetary gearbox is used to power heavy machinery in the sugar milling process. The gearbox is composed of a number of gears organized in a planetary configuration. The sun gear is located at the center, surrounded by several planet gears,and held in position by a carrier. The outer ring gear meshes with the planet gears. The planet gears spin on their axes and circle around the sun gear as it spins. As a result, the carrier rotates, driving both the mill rollers and the exterior ring gear.

The planetary gearbox provides a compact and efficient way to transmit power from the sugar mill motor to the mill rollers. Acceleration and speed decrease enable efficient sugar cane crushing and extraction.

PLANETARY GEARBOX INSTALLATION PROCESS:

Before fitting the gearbox, it is important to set up the mounting surface, foundation, and anchor bolts. Accurate alignment is essential for proper operation of gearbox and motor. The anchor bolts attach the gearbox to the foundation. In order to guarantee that the shafts of the motor and gearbox are precisely aligned, the coupling must be properly positioned. Testing gearbox at various speeds and loads to ensure proper operation.

KEY FEATURES:

- High precision, carrying capacity, tooth surface hardness, speed, dependability, and transmission efficiency.

- High power density, small size, light weight and compact structure.

- Several planet wheels transfer load at the same time.

- Low noise, low cost, modular, and standardized.

- Extensive range of transmission ratios.

TYPES OF GEARS USED IN PLANETARY GEARBOX:

The specific types of gears used in a planetary gearbox depend on the application requirements and desired output speed and torque:

- Sun gears: The sun gear is a central gear in the planetary gearbox that transfers power to the output shaft.

- Planet gears: Planet gears rotate around the sun gear, transferring power to the output shaft.

- Ring gears: The ring gear transmits torque and speed to the load.

- Helical gears: Helical gears reduce noise and vibration in planetary gearboxes.

- Spur gears: Spur gear provides high efficiency and torque transmission.

- Bevel gears: Bevel gears transmit power at an angle in the planetary gearbox.

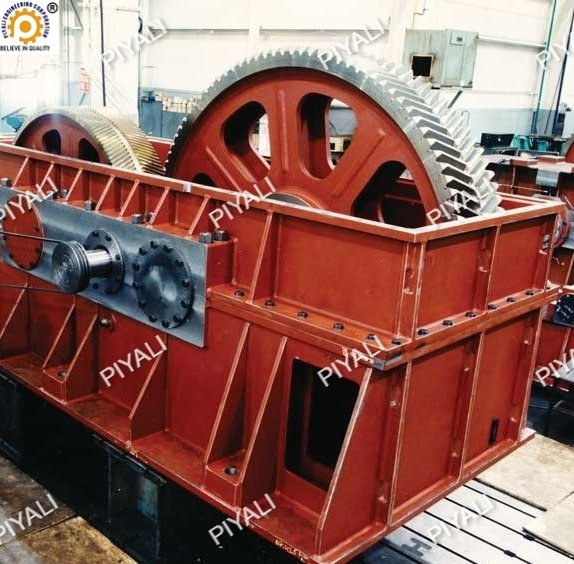

DOUBLE HELICAL GEARBOX:

A brand-new 1-stage gearbox that features 2 double helical gear sets is manufactured by Piyali. A gearbox that utilizes this design has fewer rotating components and is no longer subject to internal axial pressures. A double helical gearbox is a form of gearbox that transfers power between rotating shafts using two helical gears. When a lot of torque is needed, this kind of gearbox is frequently used in heavy-duty tasks.

SUGAR MILL CANE CRUSHERS:

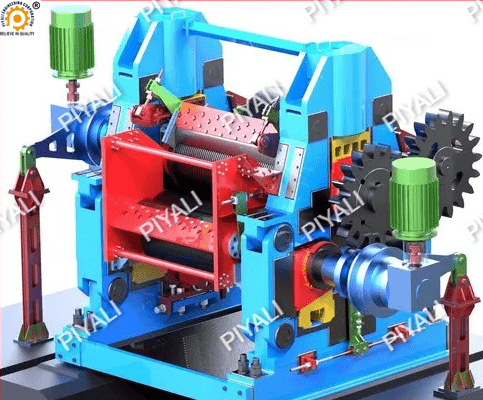

Sugar cane crushers are machines that crush sugarcane to extract juice and process it into sugar. To extract the juice, the machine consists of a set of rollers that rotate in opposing directions and crush the sugarcane between them. To resist the high pressures and forces generates during the crushing process, the cane crusher is typically use strong materials such as cast iron or steel.

Sugar Cane Crusher Rollers Rolls:

Sugar cane crusher rollers rolls operate by applying pressure to the sugar cane as it moves between them. A chute feeds sugar cane into the mill, and rollers grab the cane and drag it through the mill. The pressure between the rollers squeezes the juice out of the sugar cane as it travels through them. The juice exits the mill via a spout and accumulates in a container. Cast iron is a popular material for sugar cane crusher rollers due to its cost and wear resistance.

Rollers use grooves or spikes to grip sugar cane.This ensures proper crushing. Grooves can be adjusted to maximize crushing process for sugar cane varieties.

Sugarcane crusher mill stand housing and rollers:

The stand housing and rollers of a sugarcane crushing mill, which remove juice from sugarcane, are important parts of the machine.The heavy-duty mill stand housing houses the juice extraction system and holds the rollers, which are responsible for crushing the sugarcane and extracting the juice. The mill stand housing typically consists of cast iron or steel and aims to resist the significant loads and stresses of the sugarcane crushing process. To ensure that the crushing of the sugarcane proceeds easily and effectively, it is crucial to maintain the mill stand housing and rollers.

SUGAR CANE CHOPPER:

The agricultural tool known as a sugar cane chopper cut and shred sugar cane into smaller bits. Chopper is an essential tool for harvesting sugar cane.

Cane sprocket:

Sugar cane sprockets that transmit force and momentum between two rotating shafts via a chain. They function by transmitting motion and force from the engine to the cane-chopping blades, which then cut and gather the cane. The sprocket has a structure with a specific number of teeth that fit into the chain’s links. The idler rotates the cutting blades as it moves the chain alongside it.

KEY FEATURES:

- Sugar mill sprockets transmit power efficiently to ensure efficient operation.

- High-quality sugar mill sprockets reduce downtime and maintenance costs.

- Maintenance of sugar mill sprockets reduces the risk of accidents and equipment damage.

- High-quality sugar mill sprockets can reduce operating costs and increase profits.

Sinter spike roller:

A sinter spike roller is a type of roller that consists of small spikes or teeth arranged in a spiral pattern.The sugar cane is fed through a series of rollers during the sugar extraction process, which crushes it to release the juice. Sinter spike roller breaks down sugar cane fibrous material to extract juice.

KEY FEATURES:

- Sinter spike roller helps reduce soil compaction and improve crop yields.

- Sinter spike roller improves soil aeration, promoting root growth and plant health.

- Sinter spike roller helps control weeds by disturbing their root systems.

- Sugarcane plants require less fertilizer, resulting in cost savings.

- Sinter spike rollers improve soil health and plant growth, leading to increased crop yields and profits.