We Piyali Engineering Corporation Offers a wide range of kiln and cooler machinery spare parts and equipment like kiln and cooler Girth Gear, Rotary Kiln tyre with shell, Pinion, Tyre, Support roller, Thrust Roller, Plumber block, bearing housing, labyrinth rings (Bearing sleeves), Spring plates, End cover, End plate, Nut bolts and washery pins.

We offer you a huge range of Kiln and Cooler machinery spare parts and equipment in ready stock.

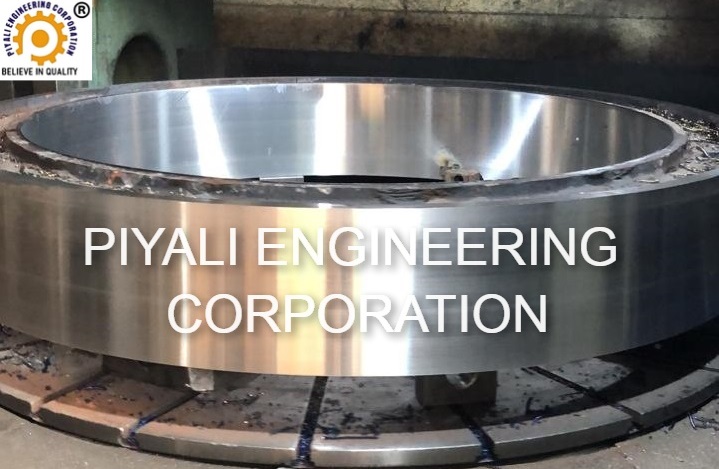

Introduction of rotary kiln tyre

Rotary kiln tyre is also called rolling ring, rotary kiln wheel belt, which is the main part of rotary kiln. The function of tyre is to transfer the whole weight (including firebrick, interior device and material) to riding wheel to make barrel stably move round at riding wheel. Therefore, tyre should have excellent strength and wear resistance; meanwhile, it is the part to enhance radial stiffness of barrel, so it should be with excellent stiffness.

Rotary kiln wheel belt features

- High strength of tyre and good durability.We produce the rotary kiln belts with material of C-45 and C-42CrMo4, that can guarantee the strength and toughness of the belts and thus play a supporting role.

- The wheel belt is treated with advanced double-medium quenching process in the casting process, which is highly adaptable.

- The rotary kiln tyre has a simple structure, which is easy to manufacture and maintain.

- Our company can process all kinds of rotary kiln belts according to customers’ drawings. The optimized technology and excellent quality can ensure that the processed rotary kiln belts are well matched with the original rotary kiln equipment.

Material Built up capacity

All machinery spare parts capacity 50 TPD, 75 TPD, 100 TPD, 200 TPD, 300 TPD, 350 TPD, 500 TPD, 600 TPD, 650 TPD and 900 TPD Sponge Iron Plant Equipment Rotary Kiln and Cooler Shell Machinery spares.

Material : all standard as per Chemical and Physical Compositions. Cast Steel Gear IS 2708 Grade – 2, 3, IS 2644 Grade C 45, IS 2644 Grade CS 700, GS30CrNiMo8, C42CrMo4, 36Mn5, GS30Mn5, 30CrNiMo8, 26NiCrMoV11-5, GS20Mn5 and Forged Steel Gear En – 9, En – 19, En – 24. Up to 1500 mm outer dia.

Rotary Kiln Tyre with Shell Ready Stock

Kiln tyre

100 Tpd Kiln tyre 3870 mm OD. width 500 mm ID 3064

MOC cast steel IS 2708 Grade 2

Kiln shell

1500 mm length shell IS 516 grade 70 Boiler quality. As per popuri design

Quality : Piyali Engineering Corporation is the highest level quality maintained company. We stand on Third party inspection like Tata Projects Ltd, TUV-Nord, SGS Inspection. (As per purchase order terms and conditions and QAP).

Applications

We offer a wide range of all kind of machinery spare parts and equipment for Sponge iron plant (DRI), cement plant rotary dryer, cement plant rotary kiln, cement plant ball mill mixing grinding unit, sugar mill dryer, paper mill dryer, paint industries mixing dryer, soy sauce residue dryers, phosphate rock slag,

Adipic acid plant, sodium percarbonate plant, soda ash plant, refined salt, sodium percarbonate, anhydrous sodium sulphate, potassium chloride, potassium nitrate, ammonium chloride, ammonium nitrate, ammonium sulfate, calcium chloride, calcium hypochlorite, calcium sulfate, granulated porcelain clay, Granulated fertilizer, iron sulfate, potassium carbonate, potassium chlorate, potassium phosphate,

potassium tartrate sludge, sodium hydrogencarbonate, sodium bromide, sodium chlorate, sodium formate, PVC, CPE, PC, chemical, mining, pharmaceutical, food, feed industrial, municipal sludge treatment industries, choline chloride, sodium bicarbonate, potassium chloride, magnesium sulfate, feed yeast, ammonium nitrate, calcium chloride, calcium hypochlorite, potassium carbonate, potassium sulfate, sodium carbonate,

sodium hydrogencarbonate, sodium metasilicate, potassium nitrate, slag, metal powder, diatomaceous earth kaolin, starch residue, distiller’s grains, dregs, soy sauce residue, phosphorus fertilizer sulfur Ammonium, light calcium carbonate, clay, lime slurry, ore mud, phosphate rock slag, Dispersing Rotary Dryer, sludge drying, municipal sludge, paper sludge, printing and dyeing sludge, blending combustion of power plant boilers, Steel making sludge, brewer’s grains, phosphate rock powder, penicillin slag, antibiotics residue, pomace, sauce residue, Steam Rotary Dryer, rotary kiln hazardous waste, paper mill recycling unit and etc.

We have supplied materials in India ( West Bengal, Jharkhand, Chhattishgarh, Raipur, Raigarh, Pune, Maharashtra, Mumbai, Tamil Nadu, Chennai, Kolkata, Durgapur, Asansol, Purulia, Jamshedpur, Ranchi, Odisha, Orissa, Bhubaneshwar, Karnataka, Hyderabad, Gujarat, Andhra Pradesh, Madhya Pradesh, Rajasthan, Meghalaya, Assam, Bihar etc.) and International Locations Egypt, Sudan, South Africa, Kiln Tyre Manufacturers, Tanzania, Kenya, Zambia, Saudi Arabia Emirates, United Arab Emirates, United Kingdom, Canada, Poland, Oman, Philippines etc.

Contact Us.

- M/s PIyali Engineering Corporation

- Address: 1708, Aya Nagar, New Delhi, India.

- Email : sales@piyaligroup.com

- WhatsApp : +91-7982398797

- Mobile No. : +91-7982398797