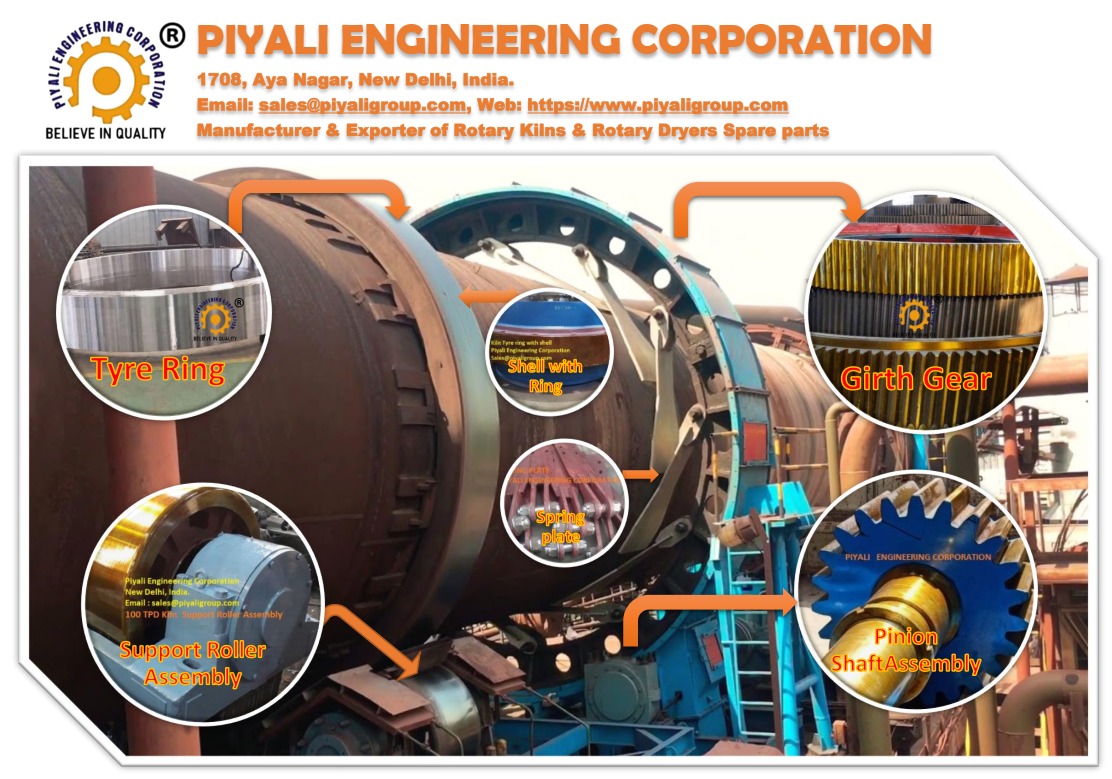

Piyali Engineering Corporation is the leading manufacturer supplier and exporter for high quality Rotary Kiln Support Roller Assembly with Shaft with Combined Bearing Housing Sleeves End Cover End Plate Bearings complete Assembly for Sponge Iron Plant DRI 50 TPD, 100 TPD, 150 TPD, 200 TPD, 300 TPD, 350 TPD, 500 TPD, 600 TPD, 650 TPD, 900 TPD Kiln Supporting Roller Trunnion Assembly and Rotary Cooler Support Roller Assembly.

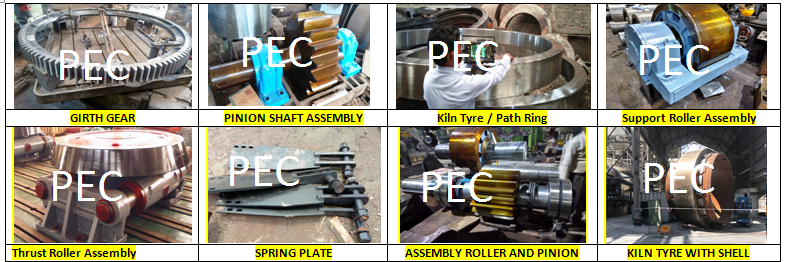

Rotary Kiln Support Roller Assembly

- Kiln Support Roller Assembly

- Kiln Support Roller shaft

- Kiln Support Roller Combined Bearing Housing

- Kiln Support Roller Sleeves / Bush / Labyrinth Rings

- Kiln Support Roller End Cover

- Kiln Support Roller End Plate / Side Plates

- Kiln Support Roller Bearings (China / TIMKEN / SKF /FAG etc.) complete assembly

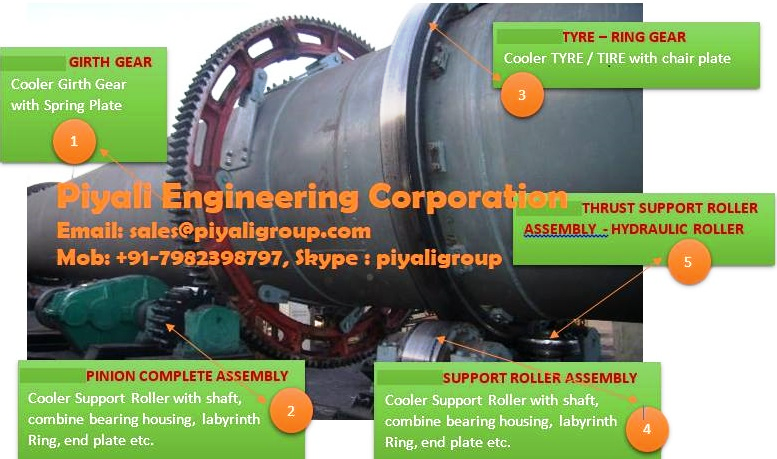

Cooler Support Roller Complete Assembly

- Cooler Support Roller

- Cooler Support Roller shaft

- Cooler Support Roller Plummer Blocks

- Cooler Support Roller Sleeves / Bush / Labyrinth Rings

- Cooler Support Roller End Cover

- Cooler Support Roller End Plate / Side Plates

- Cooler Support Roller Bearings (China / TIMKEN / SKF /FAG etc.)

Rotary Kiln Pre-heater Support Roller Complete Assembly

- Pre-heater Support Roller

- Pre-heater Support Roller shaft

- Pre-heater Support Roller Combined Bearing Housing

- Pre-heater Support Roller Sleeves / Bush / Labyrinth Rings

- Pre-heater Support Roller End Cover

- Pre-heater Support Roller End Plate / Side Plates

- Pre-heater Support Roller Bearings (China / TIMKEN / SKF /FAG etc.)

Applications: Cement Plant, Sugar Industries, Rolling Mills, Pellet Plant, Dolomite Rotary Dryer, Bauxite Rotary Kilns, Activated Carbon Plants, Fertilizer, Chemical, phosphate, mining and minerals plants.

Supporting Roller Capacity : 100mm dia to 2250mm dia.

Material : EN-9, EN-19, Cast Steel En-24, IS 2708 Grade – II/ III, GS20Mn5 as per client requirement.

Supporting Roller Manufacturing Process :

- Approved design Support Roller from client

- After approved design from client make wooden pattern

- Casting pouring (Check Chemical Properties for Test Piece)

- After casting complete clean casting and process Heat Treatment

- Rough Machining (Prof Machining) and check Ultrasonic Test, hardness Test, and relevant test as per client requirement

- Final Machining and Drilling

- Anti Rust Paint

- Wooden and Poly packing

- Dispatch.

Sponge Iron Plant Rotary Kiln Support Roller Assembly Manufactuerer

Piyali Engineering Corporation is a company based in India that provides engineering and manufacturing solutions for various industries such as cement, mining, sugar, and power plants. The company is known for its expertise in manufacturing heavy industrial equipment such as kiln shells, kiln tyres, rollers, and gearboxes.

There are several reasons why Piyali Engineering Corporation is popular worldwide:

- Quality of products: The company is known for its high-quality products that are made using advanced technology and materials. This has helped the company gain a reputation for reliability and durability.

- Competitive pricing: Piyali Engineering Corporation offers its products at competitive prices, making it an attractive option for businesses looking to save on costs without compromising on quality.

- Timely delivery: The company is committed to delivering its products on time and has a reputation for meeting deadlines.

- Excellent customer service: Piyali Engineering Corporation has a team of knowledgeable and experienced engineers who provide excellent customer service, ensuring that clients’ needs are met.

- Wide range of products: The company offers a wide range of products, including custom solutions, which makes it a one-stop-shop for many businesses.

Overall, Piyali Engineering Corporation’s commitment to quality, competitive pricing, timely delivery, excellent customer service, and wide range of products has contributed to its popularity worldwide.