Cold Rolling is a continuous high speed deformation process, keeping the temperature below the crystallization point. The material produced after cold rolling can be sold as full hard Cold rolled steel, without annealing and with a low ductility. It requires for use a later stage of annealing or galvanizing.

The Piyali Engineering Corporation is one of the best and vast manufacturer supplier and exporter of High Quality Cold Rolling Mill Machinery Parts in New Delhi, Ghaziabad, India.

List of Equipment for High Quality Cold Rolling Mill Machinery Parts

- Chocks

- Segment

- Sleeve

- Guides

- Stand

- Gears

- Pinions

- Housings

- Manipulators

Chocks

The housing of a work roll or backup roll bearing is known as roll chock or simply chock. Chock is the basic part of a rolling mill.

Guides

Roller Guide for rolling mill are a series of rollers that determine the angle and direction of the steel as it is guided through the rolling mill to the mill roll.

Stand

Universal mill stand –The universal rolling mill stand is a four way rolling stand used in the rolling of section normally beams, where in the section is shaped from all four sides. Vertical rolls are used to control the width of the work piece bar simultaneously during rolling.

Gears

Girth gears are used to drive large, rotating systems such as dryers, rotary kilns or horizontal mills.

Pinions

A pinion is a round gear—usually the smaller of two meshed gears—used in several applications, including drive train and rack and pinion systems.

The pinion gear connects to the steering shaft so that the gear will spin and move the rack when the steering wheel turns.

Housings

A mill housing is a large structure that supports the rolls used in the rolling process, and absorbs weight from the process to make the process smooth. It consists of a drive side and work side.A plate moves between the sides to be press rolled.

As most of the rolling mills work in a complicated environment, during the working process, heavy shocks will be produced from rollers to the mill housing, which may cause the inside surface and the bottom surface of mill housing into corrosive wear problem in varying degree.

Thus, the gap between the rolling mill stand and the roller bearing chock may exceed the limit value that can be controlled.

The working condition of main transmit system may also be deteriorated by the extended gap, which increases the transmit system’s vibration shock.

The steel ingot will slip while it is biting. Thus the strip shape will also be affect and so does the product quality.

Our export destinations for High Quality Cold Rolling Mill Machinery Parts:

High Quality Cold Rolling Mill Machinery Parts manufacturer in India. Our export market are Angola, algeria, iran, iraq, UAE, qatar, Saudi arabia, nigeria, east africa, south africa,

libya, bahrain, egypt, europe, asia, russia, norway, germany, framnce, italy, united kingdom, singapore,

malaysia, indonesia, thailand, vietnam, oman sudan kuwait, turkey, yamen, syria, jordan, cyprus, equatorial guinea, republic of congo, gabon, spain, south korea, ukrain, japan, netherland, sri lanka,

moreover in belgium, maldives, greece, bangladesh, czech republic, mayanmar, portugal, taiwan, hungary, cambodia, north america, south america, albania,

and also USA, canada, mexico, panama, costa rica, austria, south america, argentina, Puerto rica, trinidad and tobago, jamaica, bahamas, denmark, switzerland, slovakia, finland,

Also ireland, croatia, slovenia, malta, bolivia, brazil chile, venezuela, colombia, ecuador, guyana, paraguay, uruguay, India, andhra pradesh, raipur, raigarh, chennai, gujrat, tamil nadu, nepal,

Even in madhya pradesh, west bengal, kolkata, assam, dispur, maharashtra, bhubaneshwar, cuttack, odisha, kazakhastan, pondicherry, puducherry, and etc.

Piyali Engineering Corporation

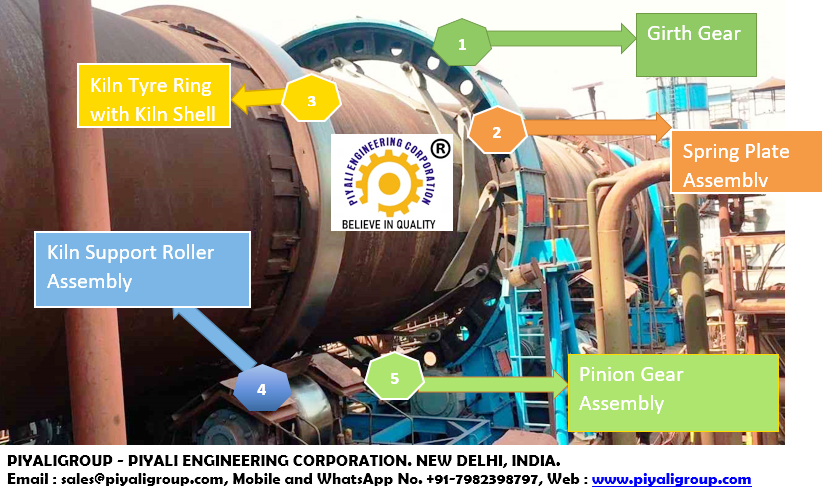

Piyali Engineering Corporation is the regular manufacturer of rotary kiln cooler and dryer machinery parts like Girth Gear, Pinion, Tyre, Support Roller Complete Assembly, Thrust Roller Complete Assembly, Bearing Housing, Spring Plate Complete Assembly, and many other items for sponge iron plant, chemical plant, cement plant, activated carbon plant and many more.

Contact Us:

For High Quality Cold Rolling Mill Machinery Parts manufacturer in India please feel free to contact us for inquiry on:

E mail Id: sales@piyaligroup.com

Mob: +91 8860239917, 7982398797

Website: www.piyaligroup.com