Piyali is the leading, well-known manufacturer and supplier of best and reliable fertilizer plant KILN spare parts. Inorganic or organic fertilizers both contain nitrogen, phosphate, and potassium, three crucial nutrients. In order to make fertilizers from raw materials like natural gas, coal, or phosphate rock, fertilizer plants usually use chemical processes. The manufacturing procedure involves a number of steps, such as raw material extraction, purification, chemical processing, granulation, drying, cooling, coating and packaging.

ORGANIC FERTILIZER PLANTS WITH RAW MATERIALS AND THEIR PROCESSING:

Piyali is the leading, well-known manufacturer and supplier of best and reliable fertilizer plant KILN spare parts. Inorganic or organic fertilizers both contain nitrogen, phosphate, and potassium, three crucial nutrients. Therefore, organic fertilizer plants use a wide range of raw materials and processing techniques to create various kinds of organic fertilizers. Some typical kinds of organic fertilizers, along with the raw materials and processing methods are:

1. PLANT BASED RAW MATERIALS:

Compost: Organic materials like animal waste, yard trash, and food waste help make compost. Raw materials decompose in a compost mound or bin.

Seaweed fertilizers: Fertilizers made from dried and powdered seaweed. Seaweed is an excellent source of micro-nutrients and trace elements.

Wood ash: Wood ash is a byproduct of burning wood that contains some trace minerals and is an excellent source of potassium.

Cottonseed meal is an excellent source of nitrogen, phosphorus, and potassium.

2. ANIMAL BASED RAW MATERIALS:

Bone meal: Animal bones that are crushed into a fine powder are used to make bone meal. Before being ground into a powder, the bones are usually boiled to remove any flesh or fat.

Blood meal: The dry animal blood afterwards transform into blood meal. Nitrogen is an excellent fertilizer and source of nitrogen for plants.

Manure-based fertilizers: These fertilizers typically originate from animal waste and other organic materials like straw, sawdust, or wood chips.

Fish emulsion: Fish waste helps to create fish emulsion.

Feather meal: Feather meal is an excellent source of nitrogen for plants because chicken feathers are made from ground-up chicken feathers.

3. MINERAL BASED RAW MATERIALS:

Micro-nutrient fertilizers: Fertilizers rich in micro nutrients have trace quantities of minerals like iron, copper, zinc, and manganese.

Rock phosphate, potassium chloride, sulfur, and sulfur are naturally occurring minerals extracted from subterranean sources.

Gypsum: This mineral originates from deposits around the world. It is often used in the production of calcium and sulphur-rich fertilizers.

PROCESSING OF ABOVE RAW MATERIALS:

Piyali is the leading, well-known manufacturer and supplier of best and reliable fertilizer plant KILN spare parts. During the raw material preparation stage, first collect and organise raw materials for processing.

- Composting: The plant-based raw materials combine and left to break down in a mound of compost.

- Grinding: Animal-based basic materials grind into a fine powder, including both bone meal and blood meal.

- Mixing: Both ground animal-based and composted plant-based raw materials mix together to create mineral-based materials.

- Pelletizing: A pelletizer machine that forms the combined components into pellets.

- Drying: To get rid of extra moisture and stop spoilage, the granules dries.

- Cooling: To avoid moisture and agglomeration, heated particles are cool down.

- Filtering: After cooling, the pellets pass through a screening mechanism to remove any oversize or undersized pellets.

- Packaging: To facilitate shipping, the finished pellets pack into bags or containers.

Fertilizer product line includes basic fertilizers:

1. NPK Fertilizer:

It’s essential to use NPK fertilizers carefully and refrain from over-application, which can result in soil nutrient imbalances and environmental damage. NPK fertilizers are available in a variety of shapes and sizes, including granules, powders, and liquids. They can be either organic or inorganic.

- Nitrogen: Nitrogen is essential for the development of chlorophyll, which enables plants to produce energy from sunlight, and is crucial for plant growth. Natural gas, ammonia, or urea are all possible sources of nitrogen.

- Phosphorus: Phosphorus is essential for the formation of roots and flowers.

- Potassium: Potassium is essential for the plant to remain strong and healthy always. Both Potassium chloride and potassium sulphate are sources of potassium.

PROCESSING STEPS: The processing steps that comprise the production of NPK fertilizer vary according to the specific manufacturing process and machinery at work. NPK fertilizer blends raw materials in a specific ratio, breaks them down and grounds them into a fine powder, which is then fed into a granulator to create granules of a particular size and shape. After that, the granules dry and cool down to room temperature for further processing. Then pack the final product into bags or containers.

2. DAP Fertilizer:

Diammonium phosphate, also referred to as DAP fertilizer, is a typical fertilizer that includes both nitrogen and phosphorus.

The following are the steps that are necessary for making DAP fertilizer:

- Mixing: To create ammonium phosphate slurry, phosphoric acid and ammonia mix together in a reactor tank.

- Reaction: Ammonium phosphate slurry is heated to 90-95°C to form DAP fertilizer.

- Granulation: Solid DAP fertilizer is granulated into pellets using granulation equipment. Granulation improves handling, storage, and application of DAP fertilizer.

- Drying: Fertilizer pellets are dried in a rotary drum dryer to remove extra moisture.

- Cooling: Cooling process involves drying fertilizer pellets to room temperature.

- Cleaning and sizing: Remove oversize or unsize particles to ensure uniform product size.

- Coating: Fertilizer pellets are coated with extra nutrients or additives to enhance their function or appearance.

- Packaging: Finally, Pack the product into bags or containers.

3. Urea Fertilizer:

Nitrogen-rich fertilizer known as urea comes from ammonia and carbon dioxide.

The following are the processes which involve producing urea fertilizer:

- Synthesis of ammonia: Synthesis gas occurs when natural gas or other hydrocarbons combine with steam to produce ammonia. The Haber-Bosch process then transforms synthesis gas into ammonia with a catalyst.

- Carbon dioxide restoration: Carbon dioxide is gathered from various sources such as fermentation processes, flue gases, and natural gas. purified and compacted carbon dioxide are used to produce urea.

- Urea synthesis: The urea synthesis reaction combines ammonia and carbon dioxide to form urea. Vacuum evaporation increases the concentration of urea.

- Urea granulation: The diluted urea solution is then fed into a granulator to form small, uniform granules. Granules are then dried in a rotary dryer to remove moisture.

- Cooling and testing: To guarantee a uniform product size, the dried urea granules are cooled and screened to ensure uniform product size.

- Packaging: After that, the finished urea fertilizer product is finally packaged into bags, containers, or bulk storage tanks.

Fertilizer production involves three main processing steps:

Piyali is the leading, well-known manufacturer and supplier of best and reliable fertilizer plant KILN spare parts. A combination of kiln, cooler, and dryer steps play a vital role in the production of various fertilizers, however the exact procedure of all these processes as follows:

- KILN: In the kiln processing step, high temperatures apply to raw materials to initiate chemical reactions and transform them into a more useful shape.

- Finished product: The finished product of the kiln is clinker, a porous, hard material that includes the desired chemical compounds for fertilizer production.

- COOLER: After the kiln process, the hot product proceeds to cool in order to lower its temperature and stabilize it. The purpose of this stage is to prepare the product for further processing and to stop further reactions from happening.

- Finished product: The finished product, clinker, is then cool down and ready to available for processing at the cooler’s output.

- DRYER:In the final manufacturing stage, the cooled product dries to remove any remaining moisture and prepare it for distribution and storing. Numerous techniques, such as belt dryers, fluidized bed dryers, and rotary dryers help to complete the drying process.

- OUTPUT AND PACKAGING: The dryer produces dry, granular material as an output that is prepare for packaging and distribution as a finished fertilizer product.

WHY CHOOSE PIYALI TO BUY EQUIPMENT FOR FERTILIZER PLANT?

Piyali Group is the leading, well-known manufacturer and supplier of best and reliable KILN spare parts for various high-quality industrial components, and sub-assemblies for different plants such as, DRI-Sponge Iron Plant, Steel Plant, Fertilizer Plant, Activated Carbon Plant, Cement Plant, and other projects and industries.

- Piyali offers efficient, reliable, and cost-effective. equipment.

- Piyali Group is well-known for its excellence and commitment to client satisfaction.

- Piyali Group’s competitive pricing makes their equipment affordable for a wide range of industries.

- Piyali Group offers cost-effective and low-maintenance equipment for businesses.

- Piyali ensure Advanced technologies and quality materials high performance and durability.

- Piyali offers customized solutions to meet customer needs.

- Our equipment is easy to install, operate, and maintain, making it popular with businesses looking for cost-effective solutions.

- Piyali Group’s quality, reliability, and cost-effectiveness are key to success in the industry.

List of equipment and machinery commonly used in a fertilizer plant:

1. ROTARY KILN:

Piyali is the leading, well-known manufacturer and supplier of best and reliable fertilizer plant KILN spare parts. Rotary kiln is the “heart” of the fertilizer plant. In order to produce fertilizers, rotary kilns handle a variety of raw materials at high temperatures, including minerals, organic compounds, and other compounds. The rotary kiln performs the chemical reaction known as calcination, which entails heating a substance to release carbon dioxide and produce a different substance.

Rotary Calcination Process:

- The kiln basically consists of a large, rotating cylinder that heats up to high temperatures.

- Rotary calcining kilns produce materials through calcination process.

- The material is constantly fed into one end of the rotary kiln’s cylinder, heated and processed, and then moved slowly to the other end.

- In addition to facilitating effective heat transmission between the material and the heating elements, the rotation of the kiln contributes to uniform heating and processing of the material.

WORKING PROCESS OF ROTARY CALCINATION KILN:

The rotary kiln is a complex piece of EQUIPMENT, and the use of spare parts such as gears, pinions, rings, and rollers plays an crucial role in its operation. Here is an explanation of how a rotary kiln operates in a fertilizer manufacturing plant:

- Preparing the Raw Materials: The process starts with gathering the raw materials ready to go into the rotary kiln. Crushing, grinding, and filtering the materials are all prevalent in this process to make sure they are of the correct size and composition.

- Loading the Kiln: Load the raw material at one end of the rotary kiln. The raw materials progressively move to the other end of the kiln as it slowly rotates around its axis.

- Heating and Calcination process: The raw materials heat up to extremely high temperatures as they move through the kiln. The heat causes chemical and physical changes to occur, leading to the production of different materials.

- Cooling and Discharging process: The raw materials are cooled as they progress towards the kiln’s end. The material is then processed before being used to make fertilize.

LIST OF EQUIPMENT FOR ROTARY KILN:

The spare parts, such as gears, pinions, rollers, and rings, are crucial to the above process because they ensure the rotary kiln’s accurate operation.

Gears and Pinions: Piyali is the leading, well-known manufacturer and supplier of best and reliable fertilizer plant KILN spare parts. These spare parts ensure that the rotary kiln rotates at an appropriate speed by transferring torque from the motor to the rotary kiln. It is a large ring gear that fits around the rotary kiln’s edge.

Girth Gear:

The girth gear is responsible for transmitting the rotary motion from the motor to the rotary kiln. It is an essential part of the rotary kiln that needs to be produce with high precision.

Pinion Gear:

The pinion gear is a small gear that transmits the rotary motion from the motor to the girth gear. A pinion gear work in pairs to transfer and adjust rotary motion and power.

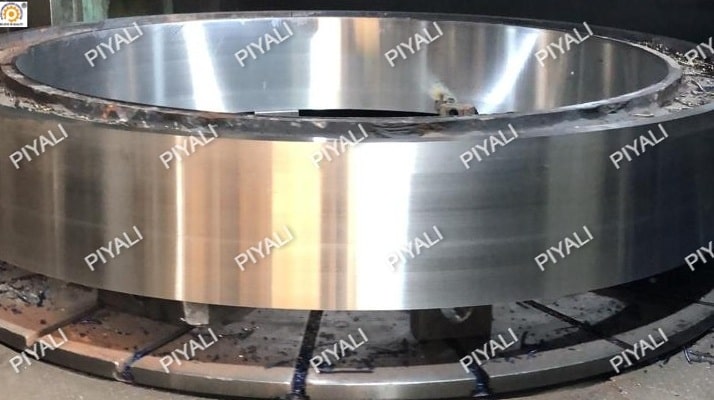

The riding ring : (KILN TYRE)

The riding ring helps distribute kiln weight evenly across the support rollers. This ensure the kiln rotates smoothly and without wobbling. As the kiln heats up and cools down, it expands and contracts. Riding ring must accommodate movements without affecting kiln stability. Regular maintenance of the riding ring is essential for its proper functioning.

Support Rollers:

Support rollers support the weight of the rotary kiln and help maintain a stable and balanced position. The rollers support the weight of the kiln as well as provide guidance to the kiln’s movement. Support rollers usually fit in pairs, one on each side of the kiln, and connect to one another by an axle that runs through the kiln shell.

Thrust:

A rotary kiln’s thrust is the power it applies to its supporting rollers and bearings. When operating a rotary kiln for fertilizer plants, thrust is an important component. It is essential to keep the proper thrust to ensure that the kiln runs smoothly and effectively. The mass and distribution of the material, form and geometry of the rotary kiln determine the thrust. Proper alignment is necessary for rotary kilns and its supporting components, such as the rollers and bearings to maintain correct thrust in fertilizer plants.

2. ROTARY COOLER:

Piyali is the leading, well-known manufacturer and supplier of best and reliable fertilizer plant KILN spare parts. The rotary cooler’s structure successfully transfers heat to cool air, cooling granules to desired temperature.

- The hot granules are fed into one end of the cylindrical cylinder of the rotary cooler, which spins on an axis, and the cool air blows in from the other end.

- The drum is lined with a series of lifters that help to lift and transmit the granules as they move through the cooler.

- The rotary cooler’s counter-flow design makes sure that hot granules and cool air flow in directions that oppose one another, enhancing the effectiveness of the cooling process.

- Rotary coolers are efficient and effective at cooling large quantities of hot granules quickly.

WORKING PROCESS OF ROTARY COOLER FOR FERTILIZER PLANTS:

- Through an inlet feeder, hot granules or pellets are fed into the rotary cooler.

- Hot material is exposed to outside air through a fan in the cooling area.

- The material slowly cools down as it passes through the cooler, exchanging heat with the air.

- The material emerges from the cooler through a discharge feeder once it reaches the desired temperature.

- Air pollution control devices collect dust and other particles. This helps in maintaining a secure and healthy working atmosphere and observing environmental regulations.

- Some rotary coolers circulates the cooled air back into the cooler to increase cooling effectiveness.

LIST OF EQUIPMENT FOR ROTARY COOLER:

Piyali is the leading, well-known manufacturer and supplier of best and reliable fertilizer plant KILN spare parts. Rotary coolers in fertilizer plants rely on several critical components to function properly, including the girth gear, pinion, riding rings, rollers and thrust.

- Girth Gear: Girth gear is a form of rotating wheel disc with semi-tooth cutting rings. It transfers power from the drive system to the rotating drum of the cooler, which rotates the cooling substance. Girth gears are prone to wear, fatigue, and damage due to heavy loads and thermal stresses.

- Pinion: The pinion is a small gear that meshes with the girth gear. It is responsible for rotating the girth gear and the rotary cooler drum. Pinion is prone to wear, pitting, and cracking due to heavy loads and dynamic stresses.

- Rollers: The rollers are cylindrical supports that hold the rotary cooler drum in place and allow it to rotate smoothly. The support roller assembly usually consists of two or more support rollers mounted on a shaft that runs parallel to the kiln axis and serve to support the weight of the kiln as it turns.

3. ROTARY DRYER:

Piyali is the leading, well-known manufacturer and supplier of best and reliable fertilizer plant KILN spare parts. Rotary dryers dry granular and powdered materials. They function by using a rotating drum and a stream of hot gas to evaporate moisture from the material. Rotary dryers are an efficient and reliable way to dry fertilizer materials. Manufacturers ensure high quality by monitoring temperature, feed rate, and airflow.

WORKING PROCESS OF ROTARY DRYER FOR FERTILIZER PLANTS:

Here’s a breakdown of the working process of a rotary dryer for fertilizer plants:

- Material feeding: Raw material is fed into the rotary dryer from one end. Also, make sure that the feeding material doesn’t overload the dryer.

- Heating: From the other end of the drum, hot gas injects into the rotary dryer. Gas generates by burning or using waste heat from other parts of the plant.

- Drying Process: The drum rotates, causing moisture to evaporate. To ensure that all particles expose the hot gas equally, the drum lifts and releases the material as it rotates.

- Discharging: After that, remove the material from the rotary dryer when it reaches the required moisture content.

- Gas cleaning: The heated gas dries the material, which becomes contaminated with impurities like dust and particulates. Therefore, air pollution control systems remove gases from the atmosphere.

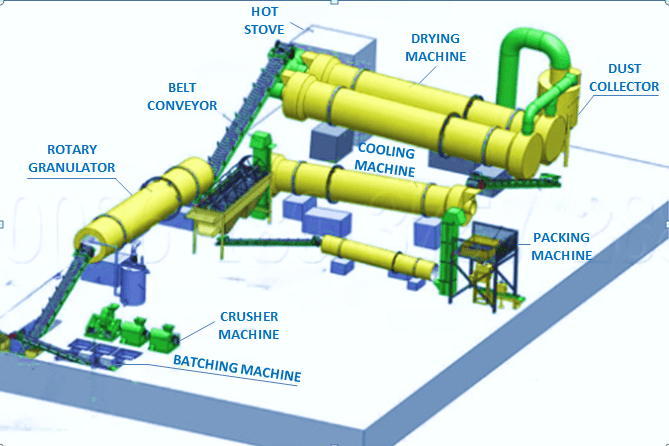

PRODUCTION LINE FLOW IN FERTILIZER PLANT:

Piyali is the leading, well-known manufacturer and supplier of best and reliable fertilizer plant KILN spare parts. The production line flow in a fertilizer plant involves several steps, as follows:

PROCESSING STEPS:

Piyali is the leading, well-known manufacturer and supplier of best and reliable fertilizer plant KILN spare parts. The Best and Reliable Fertilizer Plant Process for Kiln, Cooler, and Dryer Spare Parts is as Follows:

- Step 1: Mill (Milling)

Raw materials are milled into small particles to increase surface area.

- Step 2: Automatic Batching

Milled materials are weighed and mixed to create the desired fertilizer formulation. Measurements are essential for consistency in final product.

- Step 3: Mixer (Mixing)

The next step is mixing raw materials that ensures all ingredients are equally distributed.

- Step 4: Granulation

The fertilizer mixture is then sent to a granulator where it is formed into uniform particles.

- Step 5: Rotary Dryer (Drying)

Mixed fertilizer is then transferred to a dryer drum to remove extra moisture.

- Step 6: Rotary Drum (Storage)

The dried fertilizer is transferred to a cooler drum and cooled to room temperature. This process is essential because it prolongs the storage life of the fertilizer and stops it from clumping.

- Step 7: Rotary Screener (Filteration)

Fertilizer must be cooled to remove large particles and impurities. This step makes sure that the end product is of excellent quality and is the same size throughout.

- Step 8: Coating Machine (Coating)

Coating: After that, a thin layer of material is coated to enhance efficiency and decrease handling dust.

- Step 9: Packaging Machine (Packaging)

Packaging: The coated fertilizer is then place into bags or other packaging, prepared for delivery to farms and other clients.

Belt conveyor: Conveyor belts transport raw materials and finished products between different stages of the fertilizer plant kiln.