(DRI) SPONGE IRON PLANT

A sponge iron plant is a form of industrial plant that uses iron ore to make direct reduced iron (DRI). DRI is made by heating iron oxide (usually in the shape of pellets or lumps) in a rotary kiln with a reducing gas such as natural gas or coal. After that, the reduced iron is cooled and processed into usable shape.

350 TPD ROTARY KILN SPARES FOR (DRI) SPONGE IRON STEEL PLANT

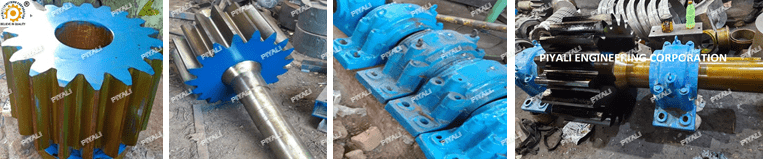

PIYALI is a well-known, trusted Indian brand and highest-quality manufacturer, supplier, and exporter of a wide range of equipment, including: Girth Gear, Pinion, Kiln Tyre, Support Roller, Shaft, Bearing Housing, Plummer Blocks, Spring Plate, Mill Head End Cover, Kiln Shells, Mill Headers, Mill Liners, Mill & Kiln Spares, Mill Girth Gears, Cast Steel Ring Gears, C.S. Bull Gears, Rolling Mill for Sugar Plant, Cement Plant, Machinery, Sugar Equipment, Sponge Iron Plant Projects, Rotary Coolers & Dryers, etc.

WHY CHOOSE PIYALI TO BUY 350 TPD KILN SPARES FOR SPONGE IRON PLANT:

- PIYALI GROUP is a manufacturer, supplier, and exporter of highest-quality kiln spares with different sizes available.

- PIYALI GROUP offers excellent supply and export services that are beneficial for businesses seeking to purchase kiln spares from a reputable supplier.

- To produce high-quality 350 TPD kiln spares with a high accuracy and precision, PIYALI GROUP employs more experienced workers and engineers.

- PIYALI GROUP conducts quality control procedures to ensure that the products meet or exceed industry standards.

Piyali Group Corporation is the proud designer and manufacturer of best-in-class 350 TPD KILN SPARES parts for Sponge Iron Steel Plant. Our products perform a variety of functions in many factories and industries. 350 TPD (tonnes per day) is the capacity of the kiln, or the quantity of material that is capable of handling in a single day in the Rotary Kiln.

350 TPD ROTARY KILN SPARES FOR DRI SPONGE IRON STEEL PLANT

PIYALI is specialized in the manufacturing of 350 TPD Sponge Iron Plant Kiln & Cooler spare parts, including the Kiln Support Roller Assembly, Girth Gear, Kiln Tyre with Shell, and Pinion Gear Assembly for 50 TPD, 100 TPD, 350 TPD, 500 TPD, 600 TPD, and 900 TPD. We can also provide forging services for rotary kiln spares with sizes 50 TPD, 100 TPD, 350 TPD, etc.

List of Manufacturing Items of 350 TPD Sponge Iron Plant Kiln spares with Their Specifications:

350 TPD KILN GIRTH GEAR FOR SPONGE IRON PLANT

350 TPD KILN GIRTH GEAR SPRING PLATES

350 TPD PINION GEAR

350 TPD KILN PINION

350 TPD KILN PINION SHAFT

350 TPD KILN PINION WITH PLUMMER BLOCK (BEARING HOUSING COMPLETE)

350 TPD KILN TYRE FOR DRI SPONGE IRON PLANT

350 TPD KILN TYRE WITH SHELL

350 TPD KILN SUPPORT ROLLER

350 TPD KILN SUPPORT ROLLER SHAFT

350 TPD KILN SUPPORT ROLLER HOUSING COMPLETE

350 TPD KILN THRUST ROLLER WITH COMPLETE ASSEMBLY

350 TPD KILN THRUST ROLLER SHAFT

GIRTH GEAR COMPLETE ASSEMBLY : 350 TPD SIZE FOR SPONGE IRON PLANT

Piyali Engineering Corporation, is an Indian company that provides engineering solutions for various industries, including sponge iron plants,activated plants, steel plants, sugar mills, cement plants, thermal power plants, and others. The company specializes in the manufacturing and supplying of Rotary kiln EQUIPMENT such as girth gears, girth gear spring plates, kiln girth gear joint bolts, and other heavy industrial equipment and spares with sizes of 50 TPD, 100 TPD, 350 TPD, etc.

350 TPD KILN GIRTH GEAR FOR SPONGE IRON PLANT:

The 350 TPD kiln girth gear is an important component in the rotary kiln system in a Sponge Iron Plant. In this product specification, the module is a millimeter-based measurement of the size of the gear teeth. The kiln’s capacity is the quantity of material they can handle in a single day. The diameter is a key factor that affects the size and power of the entire structure. The design of the tooth shape of the 350 TPD girth gear ensures smooth and effective power transmission between the driving and driven components.

350 TPD GEAR SPECIFICATION

- MODULES – 50

- CAPACITY – 350 TPD Rotary Kilns for Sponge Iron

- CERTIFICATION – ISO9001

- NO. OF TEETH – 132 Nos.

- DIMENSIONS – 6700Ø

- MATERIAL GRADE – GS34CrMo4v / IS2708 Grade – III

350 TPD GIRTH GEAR KEY FEATURES:

- With 30 years of experience, PIYALI GROUP is an expert in the manufacturing and processing of rotary kiln equipment such as: Girth gear.

- A 350 TPD kiln girth gear is typically large in size and is capable of handling heavy loads and high temperatures.

- Piyali uses CAE software to create a 3D CAD model with essential features such as sprue channels, feeders, and gating systems for simulation and the casting process.

- High-quality cast steel is used for 350 TPD kiln girth gears to ensure their durability and strength.

- Proper lubrication is necessary for 350 TPD kiln girth gears to ensure that they function smoothly.

- Heat treatment process improves girth gear hardness, wear resistance, and impact resistance.

- Proper inspection system that ensures quality through chemical composition, mechanical property, dimensional check, ultrasonic testing, MT, and PT.

- Regular maintenance is necessary to detect wear and damage and prevent serious problems if they occur.

350 TPD KILN GIRTH GEAR SPRING PLATES:

350 TPD (tonnes per day) is the capacity of the kiln, or the quantity of material that it is capable of handling in a single day. Girth gear spring plates are a type of part used in the construction of rotary kilns, which are frequently used in the production of materials like cement and sponge iron. The girth gear is a crucial component of the rotary kiln because it transfers power from the drive engine to the kiln. The spring plates reduce shock and disturbance, making the girth gear and other kiln parts last longer.

350 TPD SPRING PLATES SPECIFICATION

- BRAND – PIYALI

- CAPACITY – 350 TPD Rotary Kilns for Sponge Iron Plant

- CERTIFICATION – ISO9001

- MATERIAL GRADE – BOILER QUALITY IS 2002

- DESIGN – AS PER THE CUSTOMER NEED

350 TPD SPRING PLATES KEY FEATURES:

- A 350 TPD Girth Gear Spring plate assembly supports the girth gear of the kiln, minimizing vibrations and reducing performance.

- Spring plates provide a flexible buffer against thermal expansion and contraction, reducing wear and tear.

- Spring plates reduce maintenance and repair work, extending service life.

- Spring plates provide increased stability and reduce risk of accidents and injuries.

- Spring plates can improve the performance of the kiln by ensuring that the girth gear is operating smoothly and reliably.

350 TPD KILN GIRTH GEAR JOINT BOLTS:

For a 350 TPD kiln to function properly, the kiln girth gear joint bolts are crucial. These bolts are responsible to drive the rotation of the kiln. The girth gear drives the rotation of the kiln shell. Girth gear is held in place by joint bolts. The bolts are tightened to ensure the gear is securely fastened and operates safely. The joint between the girth gear and kiln shell must be aligned to ensure evenly distributed load and no damage.

350 TPD KILN PINION ASSEMBLY FOR SPONGE IRON PLANT

Piyali Engineering Corporation, is an Indian company that provides engineering solutions for various industries, including sponge iron plants,activated plants, steel plants, sugar mills, cement plants, thermal power plants, and others. The company specializes in the manufacturing and supplying of Rotary kiln EQUIPMENT such as Pinion gears, kiln pinion, kiln pinion with plummer blocks, and other heavy industrial equipment and spares with sizes of 50 TPD, 100 TPD, 350 TPD, etc.

350 TPD KILN PINION ASSEMBLY PRODUCT SPECIFICATIONS:

- MODULES – upto 55 Module

- CAPACITY – 350 TPD Rotary Kilns for Sponge Iron

- CERTIFICATION – ISO9001

- MATERIAL GRADE – 30CrNiMo8 / EN-24

- Test Reports – Visual Dimensional Reports, Ultrasonical Test Report, DP Test, NDE Test, MPI Test etc.

350 TPD PINION GEAR FOR SPONGE IRON PLANT:

Piyali Group Corporation is the proud designer and manufacturer of high-quality 350 TPD kiln pinion assembly products that acknowledges as some of the best in the sector. Our products perform a variety of functions in many factories and industries. Automotive, Industrial, robotics applications and consumer goods are just a few of the industries that frequently use pinion gear assemblies. The 350 TPD kiln pinion assembly consists of various parts such as kiln pinion, kiln pinion with shaft, kiln pinion with plummer block, kiln with bearing and lubrication system. The assembly includes a mounting block with a bearing inside of it.

350 TPD PINION GEAR SPECIFICATION

- MODULES – upto 55 Module

- CAPACITY – 350 TPD Rotary Kilns for Sponge Iron

- CERTIFICATION – ISO9001

- MATERIAL GRADE – EN-24, EN-19, EN-9, IS 2708 Grade – II as per clients requirement

- Test Reports – Visual Dimensional Reports, Ultrasonical Test Report, DP Test, NDE Test, MPI Test etc.

FEATURES OF 350 TPD KILN PINION GEAR:

- 350 TPD KILN Pinion gears are generally cylindrical in form and their teeth cut into the circumference of the gear.

- Simpler in design.

- The distance between adjacent teeth refers to as a pinion gear’s pitch.

- Proper lubrication is a necessity for pinion gears to prevent wear and damage from friction.

- Small and light in weight.

- A pinion gear reduces the speed of a rotating shaft. By using a pinion gear, the output shaft can rotate at a lower speed than the input shaft.

- Excellent customer service.

350 TPD KILN PINION WITH SHAFT FOR SPONGE IRON PLANT:

Piyali is the best manufacturing company for supplying rotary kiln equipment such as kiln pinion shafts with 350 TPD size specifications. A pinion shaft is a cylindrical shaft that connects the kiln drive system to the rotary kiln. The rotary kiln rotates due to the torque generated by the kiln drive system through the pinion shaft, which allows it to process the materials in the kiln. This improves the shaft’s strength and, as a result, its capacity to withstand the significant torque.

350 TPD PINION SHAFT SPECIFICATION

- MODULES – upto 55 Module

- CAPACITY – 350 TPD Rotary Kiln Pinion Shafts for Sponge Iron Steel Plant

- CERTIFICATION – ISO9001

- MATERIAL GRADE – 42CrMo4v / EN-19

- DESIGN – AS PER CUSTOMER PROVIDED (POPURI / IPS / ITC / MEC / LURGI etc.)

FEATURES OF 350 TPD KILN PINION SHAFT :

- 350 TPD Kiln Pinion with shaft transmits torque more efficiently than other types of shafts, which reduces frictional losses.

- Kiln Pinion shafts transmit power over long distances without significant power loss.

- Kiln Pinion shafts design to endure higher loads and stresses, which makes them more durable and reliable than other types of shafts.

- Pinning shafts are extremely versatile and can be used in a variety of applications, from automotive to industrial machinery.

- Pinion shafts are easy to maintain and repair.

350 TPD KILN PINION WITH PLUMMER BLOCK FOR SPONGE IRON PLANT:

Piyali Group is the leading, best-trusted, and highest-quality supplier and manufacturer of KILN PINION WITH PLUMMER BLOCK for sponge iron plant projects, rotary kilns, rotary coolers, equipment, and machinery spare parts. A Plummer block, also known as a pillow block bearing, is a form of bearing housing used to support a rotating shaft. The plummer block has an important function in the smooth and effective operation of the rotary kiln system. The base and the cap are the two main components of the plummer block that bolt together around the bearing.

350 TPD PLUMMER BLOCK SPECIFICATION

- CAPACITY – 350 TPD Rotary Kiln Pinion with plummer block for Sponge Iron Steel Plant

- CERTIFICATION – ISO9001

- MATERIAL GRADE – IS-2708 GRADE II, IS-2644 GRADE II, EN-19, EN-24 FORGED

- DESIGN – AS PER CUSTOMER PROVIDED

- Test Reports – Visual Dimensional Reports, Ultrasonical Test Report, DP Test, NDE Test, MPI Test etc.

FEATURES OF 350 TPD KILN PINION WITH PLUMMER BLOCK:

- HOUSING: The plummer block assembly includes a housing made of cast iron or steel that is designed to support the bearing and provide a reliable mounting surface.

- PEDESTAL: The pedestal (base), usually made of cast iron or steel. The pedestal is designed to provide a secure and stable base for the bearing.

- END CAP: An end cap in a plummer block is a small metal cover that seals and protects the leading edge of the pinion shaft in a plummer block assembly. The end cover helps maintain the lubricant in the housing of the bearing. This is significant because the lubricant helps reduce friction between the assembly’s rotating components, which can reduce wear and enhance efficiency.

- BEARING: The bearing is a component that enables a shaft to rotate smoothly. The bearing is mounted inside the housing, which protects it from pollution and guarantees proper lubrication.

- MOUNTING SYSTEM: The mounting system secures the bearing to the pedestal. It usually contains a set screws or secure cap that hold the bearing firmly in position and prevent it from rotating within the housing. The mounting surface must be strong and rigid enough to withstand the weight and pressure of the rotating shaft.

350 TPD KILN TYRE WITH SHELL FOR SPONGE IRON PLANT

350 TPD KILN TYRE

PIYALI GROUP manufactures and exports 350 TPD kiln tyre with shell in accordance with the designs and specifications given by clients. The 350 TPD kiln tyre is a massive steel casting that provides support to the kiln shell and the materials processed inside the kiln. This component is attached to the kiln shell and rotates on rollers or bearings, enabling smooth rotation of the kiln.

How you select a best materials grade for Kiln Tyre?

- Working conditions: The material grade should be able to handle specific loads and stresses in the kiln.

- Budget: Choosing the finest material grade for the kiln tyre will depend in part on how much the materials will cost.

- Type of process: Different kiln processes affect tyre wear and tear.

- Size and weight of the kiln: The size and weight of the kiln affect tyre loads and stresses.

350 TPD KILN TYRE PRODUCT SPECIFICATION

- MATERIAL – ASTM: 1045/ DIN: CK45/BS:080M46 Alloy Steel & Cast Iron

- CAPACITY – 350 TPD Rotary Kiln Spares

- DIAMETER – 5160

- MATERIAL GRADE – G.S.-20Mn5 / IS-2708 Grade II

- DESIGN – AS PER CUSTOMER PROVIDED

- CUSTOMIZABLE – YES

FEATURES OF 350 TPD KILN TYRE:

- High-quality steel is used to make kiln tyres so that they can endure extreme heat, weight, and wear.

- Kiln tyres are designed in such a way to handle operating kiln temperatures of up to 1000 degrees Celsius in high temperatures.

- A 350 TPD kiln tyre supports the rotary kiln and its materials.

- Kiln tyres require precision machining to fit accurately onto the kiln shell.

350 TPD KILN TYRE WITH SHELL

PIYALI Engineering Corporation is a well-known and reputable manufacturer and supplier of 350 TPD kiln tyres with shells. Here are some reasons why you should consider buying 350 TPD kiln tyres with shells from PIYALI:

- PIYALI commits to provide high-quality products.

- PIYALI offers customized kiln tyres with shells to meet customer needs.

- PIYALI works closely to understand the requirements and design of kiln tyres with shells.

- PIYALI has experienced and knowledgeable professionals who provide valuable advice and guidance to customers.

- PIYALI provides excellent customer service and support.

- PIYALI offers competitive pricing for kiln tyres with shells, providing value for money.

350 TPD KILN SUPPORT ROLLER COMPLETE ASSEMBLY FOR SPONGE IRON PLANT

350 TPD KILN SUPPORT ROLLER COMPLETE ASSEMBLY

Piyali Group Corporation is the proud designer and manufacturer of high-quality kiln support roller assembly goods that are acknowledged as some of the best in the sector. Our products perform a variety of functions in many factories and industries. A mechanical tool used in a variety of industrial applications to support and guide a moving object is a 350 TPD kiln support roller assembly. The 350 TPD kiln support roller assembly usually consists of two or more support rollers mounted on a shaft that runs parallel to the kiln axis and serve to support the weight of the kiln as it turns.

350 TPD SUPPORT ROLLER PRODUCT SPECIFICATION

- DIAMETER – 1000mmm Face width 560mm

- CERTIFICATION – ISO9001

- APPLICATIONS – 350 TPD Kiln Accessories for DRI Sponge Iron Plant

- MATERIAL GRADE – G.S.-20Mn5 / IS-2708 Grade II

- DESIGN – As per the customer requirements

- Test Reports – Visual Dimensional Reports, Ultrasonical Test Report, DP Test, NDE Test, MPI Test etc.

FEATURES OF 350 TPD KILN SUPPORT ROLLER ASSEMBLY:

- Supporting rollers are lightweight, reliable, and easy to maintain.

- Adaptability to harsh working environments.

- Powerful Machining and Heat Treatment Skills.

- Strict Quality Control and Prompt Delivery.

- Piyali uses a extremely careful inspection system that ensures quality through mechanical property, chemical composition, dimensional check, ultrasonic testing, MT, PT, and X-ray inspection.

- PIYALI has direct reading spectrometers, carbon and sulfur high-speed analyzers, and three-element analyzers to ensure chemical composition meets standards.

350 TPD KILN SUPPORT ROLLER SHAFT:

The 350 tpd support roller shaft usually has bearings on both ends to ensure smooth rotation. The bearing withstand various loads, such as axial and radial loads. The shaft may also have additional features such as keyways, grooves, or threads that allow for easy installation and alignment with other components.

350 TPD SUPPORT ROLLER SHAFT PRODUCT SPECIFICATION

- DIAMETER – 300mmm

- CERTIFICATION – ISO9001

- APPLICATIONS – 350 TPD Kiln Accessories for DRI Sponge Iron Plant

- MATERIAL GRADE – 30CrNiMo8 / EN-24

- DESIGN – As per the customer requirements (POPURI / IPS / ITC / MEC / LURGI etc.)

FEATURES OF 350 TPD KILN SUPPORT ROLLER SHAFT:

- The support shaft holds the substantial weight of the rotary kiln.

- The support roller device uses a rolling bearing wheel set for easy maintenance.

- Robust and powerful tool.

- Proper alignment and machining is necessary to ensure the smooth rotation of the kiln.

- Ensures effective and secure functioning.

- To prevent possible safety risks and guarantee the long-term dependability and performance of the kiln, proper maintenance and routine inspection of the support shaft is crucial.

350 TPD KILN SUPPORT ROLLER HOUSING COMPLETE

In a 350 TPD kiln support roller assembly, a combined bearing housing supports a rotating shaft or bearing in commercial applications. It integrates two or more types of bearings into a single housing unit to facilitate maintenance and installation of the bearing unit. They support the rotating shaft that moves the machinery. The radial bearing holds the primary load, while the axial bearing holds the side thrust.

350 TPD SUPPORT ROLLER HOUSING PRODUCT SPECIFICATION

- BEARINGS – 23160 / 24160

- CERTIFICATION – ISO9001

- APPLICATIONS – 350 TPD Kiln Accessories for DRI Sponge Iron Plant

- MATERIAL GRADE – Cast Iron / Cast steel IS 1030

- DESIGN – Standard or as per the customer requirements

FEATURES OF SUPPORT ROLLER HOUSING COMPLETE:

The following are some of the important aspects and purposes of rotating kiln bearing housings:

- Supports the bearings: The bearing housing accommodate and support the bearings that carry the weight of the kiln and the raw material.

- Protection: The bearing housing guards against contamination of the bearings by dust, grime, and other foreign objects. Additionally, it aids in cooling down the heat produced by the revolving kiln and its bearings.

- Maintenance: The bearing housing has access panels or removable covers that make it simple to examine and lubricate the bearings. For the kiln to operate safely and effectively, routine upkeep is necessary.

- Heat resistance: The bearing housing needs to be able to endure the kiln’s potentially 1000°C-plus temperatures. To prevent deformation or failure under these harsh circumstances, the materials used to construct the housing must have great heat resistance.

PURPOSE OF 350 TPD Kiln Support Roller HOUSING COMPLETE:

The primary purpose of the combined bearing housing is to maintain stability and support to the roller assembly during its rotation. The bearing enables the roller assembly to rotate efficiently or smoothly and with less friction. The bearing enables the roller assembly to rotate efficiently, smoothly, and with less friction. The combined bearing housing provides a stable and safe mounting position for the roller assembly.

350 TPD THRUST ROLLER COMPLETE ASSEMBLY FOR SPONGE IRON PLANT

Piyali Group Corporation is the proud designer and manufacturer of best-in-class 350 TPD thrust roller assembly parts FOR Sponge Iron Steel Plant, Cement Plant, Sugar Plant, and others. Our products perform a variety of functions in many factories and industries. An axial load bearing used to handle axial loads, which act parallel to the axis of rotation. A thrust roller typically consists of two thrust washers or races, a shaft, and a cylindrical roller. These cylindrical rollers are perpendicular to the axis of rotation and typically reside in a frame.

350 TPD THRUST ROLLER PRODUCT SPECIFICATION

- DIMENSIONS – 1200mm

- CERTIFICATION – ISO9001

- APPLICATIONS – 350 TPD Kiln Accessories for DRI Sponge Iron Plant

- MATERIAL GRADE – Stainless Steel, Carbon Steel, Aluminium, Zinc, PVC

- DESIGN – Standard or as per the customer requirements

KEY FEATURES OF 350 TPD THRUST ROLLER ASSEMBLY:

- PIYALI uses advanced CAD/CAE/CAM software to optimize process and ensure quality.

- Thrust roller assemblies endure high axial loads and support heavy rotating machinery.

- Thrust rollers create minimal friction, resulting in efficient transmission of forces and minimal wear.

- PIYALI uses high-quality cast steel material, which produces high-quality thrust rollers with a long service life.

- For thrust roller assemblies, materials selection is based on operating conditions, corrosion resistance, and strength.

- Thrust roller assemblies reduce stress and wear.

- Thrust roller assemblies are available in a variety of designs, such as tapered roller bearings, cylindrical roller bearings, and thrust ball bearings, which makes them ideal for a variety of uses.