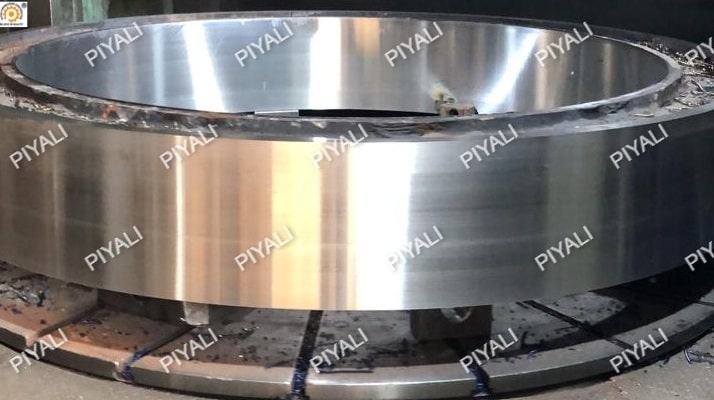

PIYALI uses radial-axial rolling technology and specially prepared raw materials to produce the nearly-net-shaped tyre. The surface of the tyre becomes uniform and smooth after rolling, which drastically cuts down on production time, enables green forging, and speeds up delivery. As a result, the forged tyres work better and last longer. In addition, we have supplied famous international firms with large rotary kiln tyre forging products with a capacity upto 8500mm.

100 TPD Kiln Tyre Dimensions

| MATERIAL | Cast Steel / Forged Steel / Ductile Carbon / Alloy Steel |

| CAPACITY | 100 TPD Rotary Kiln Tyre for Sponge Iron Steel Plant |

| CERTIFICATION | ISO9001 |

| DIAMETER | OD 3870mm |

| Capacity | upto 8500mm |

| MATERIAL GRADE | EN-8,EN-19,EN-24,GS20Mn5,32CrNiMo8V,42CrMo4,IS 2708 Grade – III,IS 2708 Grade -2 |

| DESIGN | AS PER CUSTOMER PROVIDED (POPURI / IPS / ITC / MEC / LURGI etc.) |

| CUSTOMIZABLE | YES |

Why you should buy Kiln tyre from PIYALI?

PIYALI Engineering Corporation is a well-known and reputable manufacturer and supplier of 100 TPD kiln tyres with shells. Here are some reasons why you should consider buying 100 TPD kiln tyres with shells from PIYALI:

- PIYALI commits to provide high-quality products.

- PIYALI offers customized kiln tyres with shells to meet customer needs.

- PIYALI works closely to understand the requirements and design of kiln tyres with shells.

- PIYALI has experienced and knowledgeable professionals who provide valuable advice and guidance to customers.

- PIYALI provides excellent customer service and support.

- PIYALI offers competitive pricing for kiln tyres with shells, providing value for money.

DP Testing:

PIYALI uses a non-destructive testing (NDT) technique on kiln tyres to check for surface defects in metallic and non-metallic materials.