A 100 TPD cooler tyre is a large industrial tyre (Casting Tire) used in sponge iron steel plant, cement plants, and many more to support the kiln, which is the primary piece of equipment used to produce product. The tyre serves as a support structure for the kiln and helps to evenly distribute its weight. The tyre is known as a “cooler” tyre because it is situated at the discharge end of the kiln, where hot clinker is cooled before being transported to the next stage of the manufacturing process.

100 TPD Cooler Tyre Dimensions

- MATERIAL – Cast Steel / Forged Steel / Ductile Carbon / Alloy Steel

- CAPACITY – 100 TPD Rotary Cooler Tyre for Sponge Iron Steel Plant

- CERTIFICATION – ISO9001

- DIAMETER – OD 3870mm.

- Capacity – up to 8500mm

- MATERIAL GRADE – EN-8,EN-19,EN-24,GS20Mn5,32CrNiMo8V,42CrMo4,IS 2708 Grade – III,IS 2708 Grade -2

- DESIGN – AS PER CUSTOMER PROVIDED (POPURI / IPS / IPC / ITC / MEC / LURGI etc.)

- CUSTOMIZABLE – YES

COOLER TYRE MANUFACTURING PROCESS:

A 100 TPD cooler tyre’s manufacturing process is a multi-step, complex procedure that includes various phases. The process typically involves the following steps:

STEP 1: SIMULATION

PIYALI GROUP uses casting simulation to ensure that its cast components meet the highest quality standards. This helps ensure that the finished product meets the necessary requirements and performance standards.

- CAD model design: The first step is to create a 3D CAD model of the component. PIYALI uses special software that includes essential features includes sprue channels, feeders, and gating systems.

- Material properties: The properties of the casting material (usually steel or iron) include density, specific heat, thermal conductivity, melting temperature, and viscosity.

- Boundary conditions: Boundary conditions, including temperature and velocity, are specified for each element. This allows engineers to simulate the behavior of molten metal in the mold.

- Simulation and Analysis: The simulation uses the special software, which solves the mathematical equations that govern the behavior of the molten metal. Analysis uses simulation to identify potential defects.

- Optimization: Based on the analysis, engineers can optimize the casting process by adjusting the gating system, mold design, and material properties. This helps to ensure that the casting process produces high-quality components that meet the required specifications.

STEP 2: CASTING

Casting process involves pouring the liquid material in to the mould which contains an internal cavity of the desired shape. Casting is one of the manufacturing methods used for producing COOLER TYRE. Molding molten metal into a mold to create a tyre shape and size. Sand casting is a preferred manufacturing process for cooler tyres. The procedure includes the use of a sand mold to shape the molten metal into the desired form. The sand mold is packing sand around a pattern that represents the finished tyre shape.

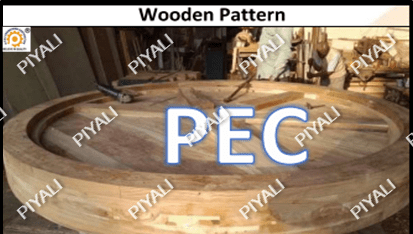

STEP 3: WOOD PATTERN

WOODEN PATTERN INSPECTION

- Dimensional Inspection: Dimensional inspection allows to check the pattern to ensure that it is of the correct size and shape for the casting.Dimensional inspection uses various precision instruments, including calipers, micrometers, and gauges, for measurements.

- Material Inspection: The material inspection is necessary to ensure that it is of high quality and complies with the casting process’s requirements.

- Surface quality: The pattern’s surface must be flawless and free of flaws like knots, fissures, or rough patches.

- Alignment: Proper alignment is essential for accurate casting.

- Inspection of the pattern assembly: In this type of inspection, the pieces should fit together correctly to make sure that there are no flaws in the joints or connections.

STEP 4: POURING PROCESS

Molding is the procedure of pouring liquid into a specific mold to ensure it solidifies in a modified form. Sand and a binding substance packs around the pattern to make a mold. To form the shape of the finished product, the molten or liquid material pours into a mold cavity or hole.The pouring process involves filling a mold with molten metal, which solidifies to form the cooler tyre.

STEP 5: HEAT TREATMENT

Heat treatment process enhances the hardness, strength, and durability of cooler tyre and their resistance. Heat treatment process improves the mechanical properties of a cooler tyre. The various heat treatments include carburizing, quenching and tempering, normalizing, and annealing. The type of heat treatment depends on the material composition of the edge and the desired mechanical properties.

HEAT TREATMENT PROCESS FOR COOLER TYRE AS FOLLOWINGS :

- Cleaning: It is the process to clean the cooler tyre properly to get rid of any debris, oil, or other impurities that could interfere with the heat treatment procedure.

- Preheating: To remove any remaining stresses and lower the possibility of thermal shock during the heat treatment procedure, the cooler tyre is preheated to a temperature of about 300–400°C.

- Austenitizing: The cooler tyre is then heated to a temperature of around 850-900°C and held at this temperature for a specified time to transform the steel into an austenitic phase. This process helps to improve the hardness and strength of the steel.

- Quenching: To quickly cool the metal and change its austenitic phase into a martensitic phase, the cooler tyre is submerged in a quenching liquid, such as water or oil. This procedure produces a material that is hard and brittle.

- Tempering: As a crucial step in the heat-treating process for cooler tyre is tempering that involves reheating the hardened tyre to a specific temperature to reduce the metal’s deformation and kept at this temperature for a predetermined period of time.

- Machining: The cooler tyre is then machined to achieve the required dimensions and surface finish.

STEP 6: MACHINING

- Rough Machining: In this procedure, the cooler tyre is first roughed out to eliminate extra material using a cutting tool, like a lathe or milling machine. This process creates the basic shape of the cooler tyre.

- Proof Machining: The cooler tyre goes through proof machining after rough machining. In this process, The tyre cut in to its final dimensions. Proof machining makes sure the tyre has the necessary measurements and adheres to the design requirements.

- Final Machining: In this step, the cooler tyre subjects to the final machining procedure, which entails polishing and completing the tyre’s surface. This procedure guarantees that the tyre’s surface is flawless and free of flaws or blemishes. The final machining procedure contributes to the tyre’s increased toughness and wear-and-tear resistance.

STEP 7: FINAL INSPECTION

Final inspection in tyre manufacturing is a critical procedure to guarantee that manufactured products meet the required specifications and are of high quality.

- DIMENSIONAL TEST: Final machining dimensional testing is a quality assurance process that makes sure the finished item or component complies with the requirements for its intended use. In dimensional test, measure the key dimensions of the cooler tyre to ensure that it meets the required specifications.

- Inspect the tyre for any visible defects.

- Measure the diameter of the tyre at various points along its circumference.

- Measure the width of the tyre at its widest point.

- Measure the thickness of the tyre at various points along its circumference.

- Check the roundness of the cooler tyre by measuring the distance between two points on its circumference.

- Compare the measured dimensions to the design specifications and margins.

- DP TEST: DP test is a non-destructive testing (NDT) method for inspecting cooler tyres for surface defects in metallic and non-metallic materials.

- DWELL TIME: A liquid dye penetrant is applied to the surface of a cooler tyre, absorbed into cracks and surface defects, and a solution is applied to remove color and highlight defects.

STEP 8: PACKAGING AND DELIVERY

- Wooden Box Packing: A wooden box can be a good choice for packing heavy equipment for storage or transportation. To determine the proper size of the required wooden box, measure the cooler tyre first. Choose a large, solid wooden box that can hold the equipment and leave the enough space for protection and security. The box needs to be strong enough to support the weight and pressure of the equipment.

- Carefully align the cooler tyre.

- Place the cooler tyre in a wooden box.

- Seal the box carefully to prevent movement.

- It is important to include all the relevant shipping information on the box’s label, along with the proper handling directions.

DELIVERY:

The 100 TPD cooler tyre with shell product is delivered to the customer.

How you select a best materials grade for Cooler Tyre?

- Working conditions: The material grade should be able to handle specific loads and stresses in the cooling process.

- Budget: Choosing the finest material grade for the cooler tyre will depend in part on how much the materials will cost.

- Type of process: Different cooling processes affect tyre wear and tear.

- Size and weight of the cooler: The size and weight of the cooler affect tyre loads and stresses.

COOLER TYRE CHAIR PAD:

The cooler tyre chair pad is a component that connects the cooler tyre to the cooler shell. A cooler tyre chair pad is commonly used to provide comfort and decrease heat while sitting in a chair. A cooler tyre chair pad’s operation consists of several stages. It uses ceramic fibre, a high-temperature, robust material that can withstand shocks and vibrations. Cooler tyre chair pad protects kiln from harm and high temperatures.

CHAIR PAD POSITIONING:

Position of chair pad with cooler tyre should ensure safe, stable, and comfortable surface for workers. The guided strip fit into a groove or channel on the surface of the cooler support, which helps to stabilize and guide the chair pad.

CHAIR PAD AND BLOCKS CONNECTION:

Blocks support and stabilize the cooler parts, and chair pads give employees a secure and comfortable place to work. Chair pad integrates with cooler blocks to support walls with some special features to fasten to blocks. It is important to ensure that the chair pad is compatible with the blocks with proper fitting to give users a stable and safe working environment in the cooler.

CHAIR PAD WORKING PROCESS:

The chair pad works in tandem with the 100 TPD cooler tyre and shell to give users of the cooler a secure and comfortable working environment. The position of the chair pad is on top of the cooler tyre, a large metal ring that holds the cooler. The outer framework of the cooler that encloses the firing chamber is cooler shell. The chair pad acts as a cushion or shock absorber, which helps to absorb any vibration or movement between the cooler tyre and shell.

MAINTENANCE: Replacement of chair pads and blocks in a rotary cooler is essential for safe and efficient operation.

FEATURES OF COOLER TYRE CHAIR PAD:

- Cooler tyre chair pad are able to withstand the high temperatures.

- Cooler tyre chair pads provide stable base for rotary cooler operation.

- Reduces risk of damage and improves efficiency and output.

- Tyre chair pads reduce wear and tear on cooler components.

- Cooler tyre chair pads improve heat transfer efficiency.

- Cooler tyre chair pads reduce downtime and increase productivity.

COOLER SHELL:

- A rotary cooler shell is usually made of steel plate, a large cylindrical furnace, is used at high temperatures for operations like annealing, roasting, and drying materials.

- Several steel plates are typically welded together to make a cylindrical shape for the shell.

- The size and shape of the cooler shell can change depending on the intended use and production needs.

- Refractory materials are used to protect cooler shells from corrosive atmospheres and high temperatures.

- The rollers and bearings that support the cooler shell allow it to gently rotate around its longitudinal axis.

- The drive system for the cooler shell, which rotates the shell, is made up of a motor, gearbox, and other components.

100 TPD Cooler Shell Technical Specifications

- CAPACITY – 100 TPD Rotary Cooler Shell for Sponge Iron Steel Plant

- CERTIFICATION – ISO9001

- MATERIAL GRADE – BOILER QUALITY (BQ) IS 2002, SA 516 Grade 70

- DESIGN – AS PER CUSTOMER PROVIDED (POPURI / IPS / ITC / MEC / LURGI etc.)

- CUSTOMIZABLE – YES

COOLER SHELL FABRICATION PROCESS:

“Cooler shell fabrication” is the process of manufacturing cooler shell. Usually, several steel plates are welded together to form the cylindrical shape of the cooler shell.

The fabrication process of cooler shells steps are as follows:

- Design: The first stage in the fabrication process of a cooler shell is design, which involves choosing the appropriate materials, determining the shape and size of the cooler shell, and other necessary specifications.

- Materials: Depending on working temperature, chemical environment, and mechanical stresses, cooler shells are made.

- Chamfering: Chamfering is the process performs to remove sharp edges, protect against scratching and cracking, and enhance the cooler shell’s appearance. Using a chamfering tool, a cutting tool, to create a beveled edge or surface is a necessary step in the chamfering process.

- Cutting and Bending: Cut and shape the raw materials into the required shape and size of the cooler shell parts. The bending process involves the shaping of a metal plate or sheet into a curved shape to create the cylindrical shell of a cooler..

- PLATE BENDING PROCESS: The plate bending process involves shaping the steel plates into the desired shape to form the shell.

5. Welding and Assembly: Welding techniques are used to join and prepare edges for welding includes GTAW, SMAW, and GMAW are used to join and prepare edges for welding. In the assembly process, the cooler shell assembles with the help of bolting or welding additional components.

6. Machining and Finishing: After the cooler shell structure is complete, it performs machining and finishing process to ensure that it is the right size, shape, and surface finish.

7. Quality Control: Quality control methods ensure the cooler shell is safe and meets production requirements.

100 TPD COOLER TYRE WELDED FITTED WITH SHELL:

Welding is the process to fit a 100 TPD cooler tyre with a shell. Other methods include shrink-fitting and bolted connections to fit a cooler tyre with a shell.

The basic procedures for welding a cooler tyre to a shell are as follows:

- Cleaning: Clean the surfaces of the 100 TPD cooler tyre and shell is the first step. Remove the dirt, rust, or other contaminants to ensure a strong bond.

- Tack welding: The next step is to use tack welds to hold the cooler tyre in place on the shell. This involves placing the small welds at specific distances all around the cooler tyre.

- Preheating: To help the weld penetrate the metal and form a solid bond, the metal is heated to a high temperature after the tack welds are in position.

- Welding: After preheating, the cooler tyre is joined to the shell by welding. This entails melting the metal and joining the cooler tyre to the shell using a welding equipment. To guarantee a solid and long-lasting bond, the welding process needs to be carefully managed.

- Cooling: After welding is finished, the metal is given time to gently cool. This is crucial to keep the metal from brittleness and to maintain the strength of the joint.

- Finishing: This process is used to remove any extra weld substance after the metal has cooled. The surface is polished to create an even, smooth, and rotating surface.

100 TPD COOLER TYRE SHELL REPLACEMENT:

The replacement of the 100 TPD cooler tyre and shell is a complex process that requires specialized knowledge and tools. The procedure consists of several steps, including disassembling the current cooler, removing the old tyres and shells, and replacing them with new parts.

Cooler tyre shell replacement process:

- Dismantling the cooler: Dismantling or Breaking the cooler is the first stage in the replacement process. This involves taking out the burner, refractory lining, and other parts of the existing cooler.

- Removing the old tyre: Remove the old tyre from the cooler by cutting the bolts and separate it from the shell.

- Removing the old shell: After removing the tyre, Split the old shell pieces out of the cooler.

- Installing the replacement tyre: Mount the new cooler tyre on the support rollers of the cooler and line up with the shell.

- Installing the new shell: Install the new shell by welding the individual pieces together and lining them up with the tyre.

- Fixing the cooler: After the replacement parts installation, add the refractory lining, burner, and other parts to the cooler.

- Checking and assembling: The final step is to test the cooler and put into service to make sure it is functioning properly.

Why you should buy Cooler tyre with shell from PIYALI?

PIYALI Engineering Corporation is a well-known and reputable manufacturer and supplier of 100 TPD cooler tyres with shells. Here are some reasons why you should consider buying 100 TPD cooler tyres with shells from PIYALI:

- PIYALI commits to provide high-quality products.

- PIYALI offers customized cooler tyres with shells to meet customer needs.

- PIYALI works closely to understand the requirements and design of cooler tyres with shells.

- PIYALI has experienced and knowledgeable professionals who provide valuable advice and guidance to customers.

- PIYALI provides excellent customer service and support.

- PIYALI offers competitive pricing for cooler tyres with shells, providing value for money.